Over our 15+ years in business, Yixing Tech has developed a niche for supplying high-quality custom aluminum fabricated and machined components, ready for assembly, to meet the diverse needs of our customers. Our state-of-the-art 70,000 Sq Ft fabrication facility is equipped with a wide range of sheet metal fabrication machines and CNC machines for cutting, forming, welding, CNC turning and milling, metal spinning and surface treatment. Additionally, our ability to deliver rapid prototypes and short-run samples further enhances our value proposition, ensuring we provide tailored custom aluminum fabrication solutions that align with our clients' unique requirements.

Expertise: Skilled engineers and technicians with extensive experience in aluminum fabrication.

Advanced Technology: Utilization of state-of-the-art machinery and software for precision and efficiency.

Customization: Ability to tailor products to meet unique client specifications and requirements.

Quality Assurance: Rigorous quality control processes to ensure high standards and reliability.

Sustainability: Commitment to environmentally friendly practices, including recycling and waste reduction.

Custom aluminum fabrication refers to the process of cutting, shaping, and assembling aluminum materials to create specific products or components tailored to a customer's unique requirements. Aluminum is a popular material for fabrication due to its lightweight, corrosion resistance, durability, and versatility.

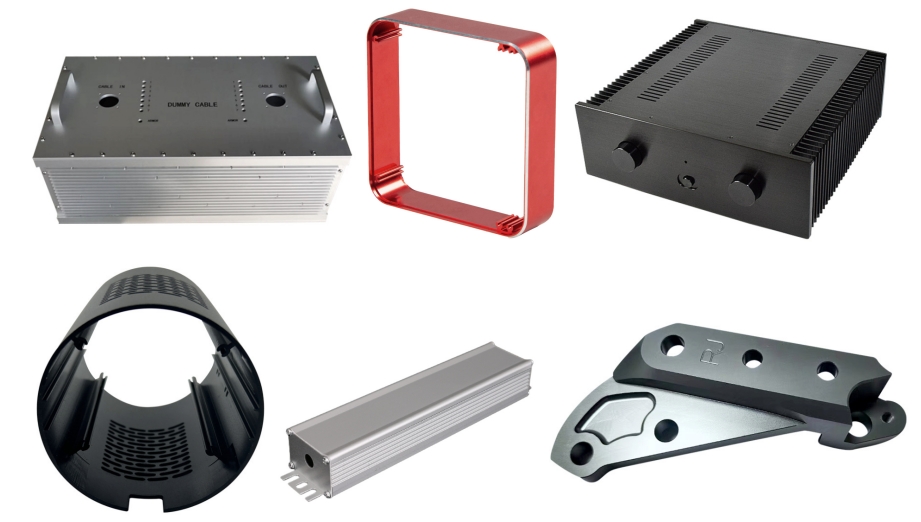

As an expert in aluminum fabrication, Yixing can do further fabrication on aluminum sheets/coils, aluminum profiles, aluminum tube and pipes, aluminum bars and rods, aluminum castings and aluminum forgings. Below is summary of our aluminum fabrication capabilities which almost cover all the processes in the metal fabrication industry. Contact us today for your one-stop service!

Cutting and Machining:

*Precision Cutting: Using advanced cutting techniques such as laser cutting, water jet cutting, and CNC machining to achieve precise dimensions.

*CNC Machining: Employing CNC machines for high-precision milling, drilling, and turning operations.

Forming and Shaping:

*Bending and Rolling: Utilizing press brakes, tube bending machines and roll forming machines to shape aluminum sheets and tubes.

*Stamping: Creating complex shapes and patterns through stamping processes.

Aluminum Extrusion&Machining:

*Aluminum Extrusion:Force heated aluminum billets through a steel die on extrusion press to create long, continuous profiles like bars, tubes, channels and special shapes.

*CNC Machining: Do secondary CNC machining like drilling, milling, turning etc to refine the extruded parts to meet precise tolerance.

Aluminum Forging&Machining:

*Aluminum Forging: Use Open-Die Forging (Free Forging) or Closed-Die Forging (Impression-Die Forging) to make aluminum 3D shaped part with high strength.

*CNC Machining: CNC operations will be done to achieve final dimensions and surface finish.

Joining and Assembly:

*Welding: Performing TIG, MIG, laser welding and other welding techniques to join aluminum components.

*Riveting and Fastening: Using mechanical fasteners for assembly where welding is not suitable.

*Adhesive Bonding: Applying industrial adhesives for specific applications requiring bonding.

Finishing:

*Surface Treatments: Offering anodizing, powder coating, and painting to enhance appearance and corrosion resistance.

*Polishing and Brushing: Providing aesthetic finishes for a polished or brushed look.

Aluminum is a popular choice for custom fabrication due to its unique combination of properties that make it suitable for a wide range of applications. Below are some key reasons why aluminum is often chosen for custom fabrication.

1. Lightweight

Aluminum is about one-third the weight of steel, making it ideal for applications where weight reduction is critical, such as in aerospace, automotive, and transportation industries.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which makes it highly resistant to corrosion. This property is especially beneficial for outdoor or marine applications, and it is also highly valued in custom marine stainless steel fabrication projects.

3. Strength-to-Weight Ratio

Despite its lightweight nature, aluminum offers excellent strength, especially when alloyed with other metals. This makes it suitable for structural applications where both strength and low weight are important.

4. Machinability and Formability

Aluminum is easy to machine, cut, weld, and form, making it highly versatile for custom fabrication. It can be shaped into complex designs without compromising its structural integrity.

Yixing Technology's custom aluminum fabrication process, with its focus on precision, customization, and quality, makes its parts indispensable across a wide range of industries. The ability to tailor components to specific needs ensures optimal performance and reliability in diverse applications.

Automotive Industry: lightweight vehicle components such as engine blocks, chassis, body panels, and suspension systems.

Construction Industry: aluminum fabricated building materials, such as window frames, doors, roofing systems, and structural supports.

Electronics Industry: aluminum heat sinks, enclosures, and housings for electronic devices.

Marine Industry: aluminum construction of boats, ships, and offshore structures.

Industrial Machinery: aluminum enclosures, covers, heavy-duty machinery and equipment.

Consumer Goods: custom aluminum parts for furniture, appliances, and sporting goods.

Medical Equipment: aluminum fabricated components for medical devices and equipment.

Renewable Energy: solar panel frames, wind turbine components, and other renewable energy systems.

Transportation: lightweight, high-strength components in trains, buses and other transportation systems.

*All In House: Unlike other factories with limited capabilities, we make all the aluminum fabrications in house—cutting, bending, metal stamping,CNC turning, CNC milling, welding etc. You can depend on us for one stop shop solution.

*Full Range of Material Selection: As a professional metal fabrication shop, we fully understand the difference between different aluminum alloys so that we can give customers good suggestions about which aluminum grade is best for their application and manufacturing method.

*ISO9001 Certified:We strictly adhere to ISO9001 quality standard to provide second to none aluminum fabrication parts. We implement IQC , IPQC, FQC and OQC in our quality control.

*Wide Applications: With our more than 15 years experience in aluminum stamping parts, aluminum deep drawing parts, aluminum weldments, aluminum machining parts, we have served customers around different industries like metal package, chemical industry, marine industry, electronic industry, locomotive components, electronic products, medical devices, and building decoration etc.

When selecting aluminum alloys for custom aluminum fabrication, people usually considers factors like strength, corrosion resistance, machinability, weldability, and budget. Yixing works with all the aluminum material grade and knows what fabrication method is suitable for different grades. You can trust us for your high precision and cost effective aluminum fabricated parts!

| 1xxx: 1050, 1050A, 1060, 1100 etc |

| It is with the highest aluminum content, with a purity of over 99.00%. Good formability and surface treatment, with the best corrosion resistance among aluminum alloys. The higher the purity, the lower the strength. 1000 series of aluminum materials are relatively soft, mainly used for decorative or interior parts. |

| 2xxx: 2014, 2017, 2024 etc |

| High hardness, but poor corrosion resistance, with the highest copper content. The copper content is around 3%~5%. The 2000 series aluminum bars belong to aviation aluminum materials and are used as construction materials. Currently, they are not commonly used in conventional industries. |

| 3xxx: 3003, 3004, 3005, 3105, 3A21 etc |

| The 3000 series aluminum rod is mainly composed of manganese element. The manganese content ranges from 1.0 to 1.5, making it a series with good rust prevention function. Commonly used as tanks for liquid products, construction components, construction tools, various lighting components, as well as various pressure vessels and pipelines for sheet metal processing. Good formability, solubility, and corrosion resistance. |

| 4xxx: 4032, 4043 etc |

| Usually, the silicon content is between 4.5% and 6.0%, and higher silicon content results in higher strength, good fluidity, and less solidification shrinkage. It belongs to the category of building materials, mechanical parts, forging materials, and welding materials; Low melting point, good corrosion resistance, heat resistance, and wear resistance. |

| 5xxx: 5005, 5052, 5754, 5083, 5A05, etc |

| The main element is magnesium, with a magnesium content of 3% to 5%. The main characteristics are low density, high tensile strength, and high elongation. The weight of aluminum magnesium alloy is lower than other series under the same area, and it is also widely used in conventional industry. |

| 6xxx: 6061, 6082, 6063 etc |

| The 6000 series aluminum alloy mainly contains magnesium and silicon elements. Therefore, it combines the advantages of the 4000 series and 5000 series. As a representative material of 6000 series, 6061 is a cold treated aluminum forging product suitable for applications with high requirements for corrosion resistance and oxidation resistance. Good usability, easy coating, and good processability. |

| 7xxx: 7075 etc |

| 7000 series mainly contains zinc element. The representative material of 7000 series aluminum alloy is 7075. It belongs to the aviation series. It is an aluminum magnesium zinc copper alloy that can be heat treated. It is a superhard aluminum alloy with good wear resistance. |