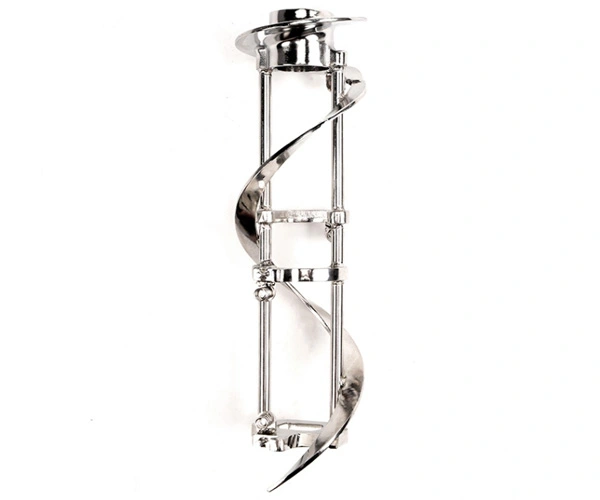

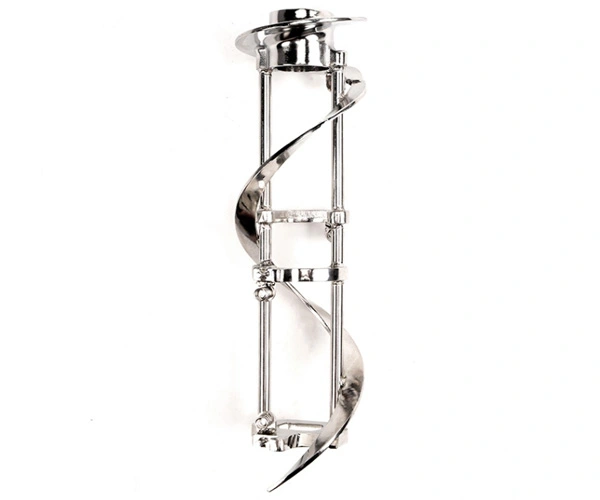

Material: SS304 SS316

Surface: electro-plating

Customized Size

Tolerance: ±0.5mm

Main process: laser cutting and welding

Electroplated welded metal spiral blade stirring shaft

The surrounding conditions during welding include: base material material, plate thickness, groove shape, joint form, restraint state, ambient temperature and humidity, cleanliness, and the type and diameter of welding wire (or electrode) determined based on the above factors, welding current, voltage, welding speed, welding sequence, deposition method, gun (or rod) transportation method, etc.

The depth of melting of the base material on the cross-section of the welded joint.

The spatial position of the weld seam during fusion welding. There are forms such as flat welding, vertical welding, horizontal welding, and overhead welding.

① During vertical welding, the welding process where the arc is carried out from top to bottom is called downward vertical welding. For example: cellulose electrode for vertical welding downwards; CO2 downward vertical welding, etc.

② During vertical welding, the welding process where the arc welding is carried out from bottom to top is called upward vertical welding.

Steel structures connected by welding methods are called welded structures.