Sheet metal processing is a type of metal processing process that typically involves manually or through die Stamping to produce plastic deformation of some metal sheets, forming the desired shape and size, and further forming more complex parts through welding or a small amount of mechanical processing. Metal sheet metal processing is called sheet metal processing, and the main processes include cutting, Bending, forming, welding, riveting, etc. It requires a certain amount of geometric knowledge. Sheet metal parts are sheet metal hardware parts, which can be processed through Stamping, Bending, stretching, and other methods. For example, the outer iron shell of a car is a sheet metal part. The metal processing processes corresponding to sheet metal technology include casting, forging, mechanical processing, etc., and the metal thickness of their products is usually inconsistent.

① Handmade sheet metal

Using relatively simple tools, most of the work is done by hand in sheet metal processing, mainly concentrated in fields such as automotive repair, art, advertising, etc

② Stamped sheet metal

With the power of conventional or special stamping equipment, the production technology of directly deforming metal plates in a mold under the action of deformation forces to obtain metal plate products of specific shapes and specifications is only applicable to product types with a relatively simple variety, large output, small structure, and relatively stable stability

③ CNC sheet metal

The use of CNC technology and equipment for comprehensive cold deformation processing of metal plates mainly includes processes such as punching, cutting, folding, welding, riveting, surface treatment, etc. It is suitable for product types with small batches, multiple varieties, and large sizes

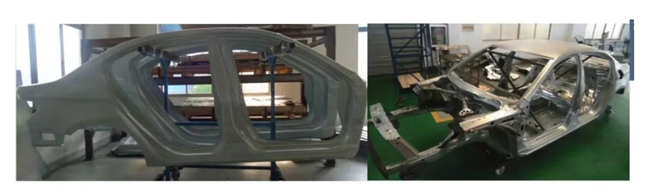

① Pressed products have good quality, such as smooth surface, high precision, relatively stable, and good interchangeability; Light weight, good rigidity, and high strength; The stamping process can also process workpieces that are difficult to process by other processing methods, such as thin shell parts, workpieces with flanges, undulations, and reinforcing ribs. The dimensional accuracy of cold stamped parts is guaranteed by the mold, so the dimensional stability and interchangeability are good.

② Stamped products do not require or only require a small amount of cutting, resulting in high material utilization and low material costs for the workpiece.

③ High production efficiency, simple operation, and easy to achieve mechanization and automation. Equipped with advanced production lines, it can achieve fully automatic mechanized operations such as feeding, stamping, picking up parts, and waste removal, with low labor intensity.

④ The molds used for pressing are generally complex in structure, with longer production cycles and higher costs. Therefore, stamping processes are mostly used for batch and mass production, while single piece and small batch production are subject to certain restrictions.

① Ordinary cold rolled sheet SPCC

SPCC refers to the continuous rolling of steel ingots into steel plate coils or sheets of required thickness through a cold rolling mill. The surface of SPCC lacks any protection and is easily oxidized when exposed to air, especially in humid environments where the oxidation rate accelerates and dark red rust appears. The surface needs to be painted, electroplated, or other protective measures when used.

② Galvanized steel plate SECC

The substrate of SECC is a general cold-rolled steel coil, which becomes an electrogalvanized product after undergoing degreasing, pickling, electroplating, and various post-treatment processes on a continuous electrogalvanizing production line. SECC not only has the mechanical properties and similar processability of ordinary cold rolled steel sheets, but also has superior corrosion resistance and decorative appearance. It has great competitiveness and substitutability in the market of electronic products, home appliances, and furniture. For example, SECC is commonly used in computer chassis.

③ Hot dip galvanized steel sheet SGCC

Hot dip galvanized steel coil refers to the semi-finished product after hot rolling, pickling or cold rolling, which is cleaned, annealed, and immersed in a molten zinc bath at a temperature of about 460 ° C, to coat the steel sheet with a zinc layer, and then subjected to quenching, tempering, leveling, and chemical treatment. SGCC material is harder than SECC material, with poor ductility (avoiding deep drawing design), thicker zinc layer, and poor weldability.

④ Stainless steel SUS301

"The content of Cr (chromium) is lower than that of SUS304, and its corrosion resistance is poor. However, after cold processing, it can obtain good tensile force and hardness, and has good elasticity. It is mainly used for spring and EM prevention.".

⑤ Stainless steel SUS304

One of the most widely used stainless steels, it has higher corrosion and heat resistance than steel containing Cr (chromium) due to its Ni (nickel) content. It has excellent mechanical properties, no heat treatment hardening phenomenon, and no elasticity.

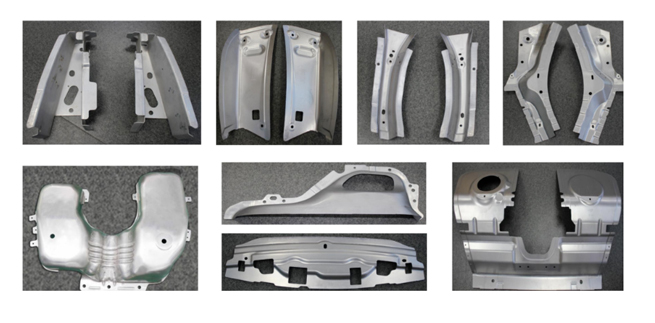

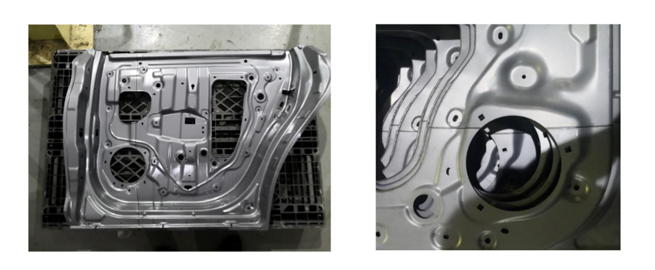

Shanghai Yixing provides automotive sheet metal processing, automotive sheet metal parts, automotive stamping parts, sheet metal design, professional manufacturing, metal processing, stamping hardware, and professional production of various shaft machines. It has strong technology, complete special specifications, and quality assurance, which can effectively reduce costs.