In Stamping dies, the value of the gap is a science and deserves careful consideration. The size of each gap determines the accuracy of the mold, the service life of the mold, and also determines the cost of the mold.

Among all gaps, the Stamping gap is the most flexible and difficult to figure out. Different materials, material thickness, product cross-section quality, and dimensional accuracy requirements will affect the value of the stamping gap.

Definition of stamping gap:

The gap value between the convex and concave dies (stamp, knife edge) used for stamping materials in the mold is called "blanking gap". formula:

Z=D-d

Note: Z——blanking gap, D——knife edge size, d——stamp size

And there is a difference between single-sided gap and bilateral gap in Z. The reasonable stamping gap is usually used as the definition standard.

Relationship between stamping quality and blanking gap

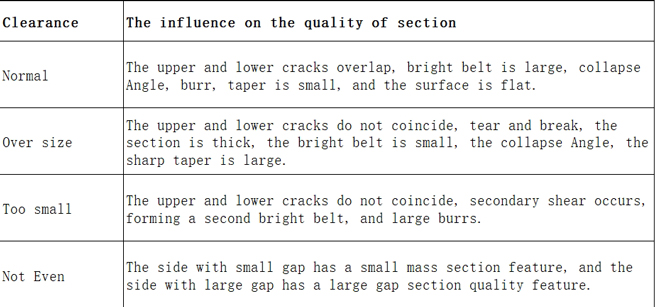

1. The relationship between blanking gap and section quality

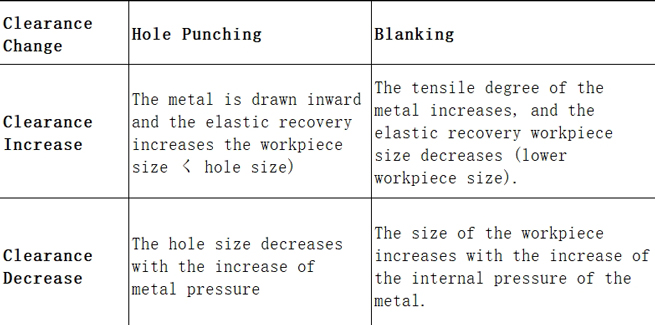

2. The relationship between stamping gap and dimensional accuracy

All materials will undergo elastic deformation during the stamping process. After the stamping is completed, dimensional deviation will occur due to elastic deformation. The gap between the knife edge and stamp can directly solve this problem.

3. The relationship between stamping gap and stamping force

When the stamping gap becomes smaller, the material deforms and the section becomes more difficult, causing the stamping force to gradually increase. When the stamping gap becomes larger, the material deforms and the cross section becomes simpler, so the stamping force gradually becomes smaller.

While the stamping gap affects the stamping force, the stripping force also follows its changing pattern. When the stamping gap is as large as 15%-20%T, the stripping force can be ignored.

4. Relationship between stamping gap and mold service life

The size of the blanking gap causes the friction between the material, the knife edge and the stamp to change. When the gap is small, the friction becomes larger, and the service life of the stamp edge is reduced. On the contrary, the service life is extended.

5. What is "reasonable blanking gap"

On the premise of ensuring dimensional accuracy and cross-sectional quality, try to increase the blanking gap to meet the needs of various indicators of the mold.

This gap is a range of values, as long as all the above requirements are met. However, you need to select according to the order of conditions:

①. There is no requirement for product cross-section quality. Try to choose a larger blanking gap to obtain a larger mold service life and smaller mold tonnage.

②. The cross-section quality and dimensional accuracy requirements of the product are relatively high, so try to select a smaller blanking gap.

6. Comparison table of common blanking gaps