If in non-standard design, surface treatment is indeed required and there are tolerance requirements for the size of the workpiece after surface treatment, but we do not know how to label it, so we specify the size in the technical requirements as the size after surface treatment.

The following are some common surface treatments that increase the general thickness, but please note that the same surface treatment may have different thicknesses due to different process flows, so it needs to be determined according to the actual situation. However, exceptions only apply to certain special processing sites. Most of them are in the framework below.

Nickel Plating

The thickness of nickel plating is generally between 0.5 and 25 μ The specific thickness between m should be determined based on the usage environment and requirements.

Generally speaking, the thicker the coating, the better its corrosion resistance and wear resistance. However, an excessively thick coating can affect the mechanical and processing properties of the material.

Chrome Plating

The thickness of chrome plating is generally 20 μ Above m, when plating hard chromium, the bottom layer is generally not treated, and the coating thickness can reach 5-80 μm. In injection molds, the coating thickness is usually 100-125 μ m. The hardness of the coating can reach over 60HRC.

Plating decorative chromium usually increases the thickness between 0.5 and 1 micrometer, and if wear resistance is required, it can be increased to 2 micrometers.

Galvanization

In China, common standards for galvanized thickness include 70 grams per square meter, 100 grams per square meter, 120 grams per square meter, 140 grams per square meter, 275 grams per square meter, etc.

Among them, thicknesses of 70 grams per square meter and 100 grams per square meter are suitable for some general steel products, while thicknesses above 120 grams per square meter are more suitable for some products that require higher anti-corrosion performance.

In addition, according to the different thickness of galvanizing, it can be divided into three levels: light, ordinary, and heavy, corresponding to three thicknesses of 30-60 g/square meter, 60-120 g/square meter, and 120-275 g/square meter, respectively.

Among them, lightweight ones are suitable for anti-corrosion in general indoor environments, ordinary ones are suitable for general outdoor use, and heavy-duty ones are suitable for special environments such as highways, oceans, etc.

The national standard GB/T2518-2020 "Continuously hot-dip galvanized steel plates and strips" specifies the standard for the thickness of the galvanized layer. The requirements are as follows:

The standard thickness of a regular galvanized layer is 20 μ m. The minimum thickness is 13 μ M;

The standard thickness of the thickened galvanized layer is 45 μ m. The minimum thickness is 30 μ M;

The standard thickness of the ultra thick galvanized layer is 78 μ m. The minimum thickness is 61 μ M.

Hard Chromium Plating

The thickness of hard chromium plating is generally 20 μ Above m, the hardness is generally 800-900HV.

Hard chromium plating is a process of depositing a thick layer of chromium coating on various substrate surfaces, utilizing the characteristics of chromium to improve the hardness, wear resistance, temperature resistance, and corrosion resistance of parts.

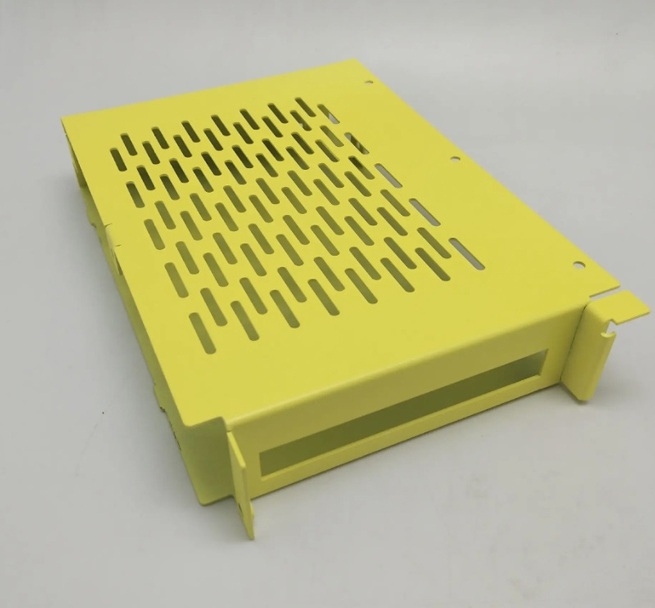

Spray Coating

The thickness of spray coating is generally between 20 μm~100 μm. Among them, the standard thickness range of common spray coating is as follows:

Ordinary coating: generally requires a spray coating thickness of 30 μm~50 μm to achieve certain anti-corrosion, weather resistance, and decorative effects.

Anti corrosion coating: For products with anti-corrosion requirements, a spray coating thickness of between 60 μm~80 μm to provide better anti-corrosion performance.

Heavy anti-corrosion coating: For products used in harsh environments, the spray coating thickness may further increase.

These thickness values and standards may vary depending on product type, application field, and other factors. In practical operation, these values need to be adjusted appropriately based on specific products and applications.

Spray Painting

The thickness of spray paint varies depending on different applications and occasions.

In the automotive industry, the paint thickness is usually required to be between 30 and 70 μm to meet the requirements of appearance, durability, and corrosion resistance.

In the construction industry, spraying technology is also widely used. The paint thickness of a building is related to its environment and function. For example, the paint thickness of indoor walls is generally thin, usually between 20 and 40 μm. The paint thickness requirement for outdoor walls may be higher, as they need to withstand more severe weather and external conditions, typically between 50 and 100 μm.

In the fields of anti-corrosion coatings, fireproof coatings, wear-resistant coatings, chemical corrosion resistant coatings, and high-temperature resistant coatings, there are also corresponding requirements for coating thickness, generally between 80-120 μ m, 100-200 μ m, 100-200 μ m, 150-250 μm and 200-300 μm.

Anodizing

The thickness of anodizing treatment varies depending on the material, anodizing method, and certain specific conditions.

Generally speaking, the thickness of hard anodizing can range from a few micrometers to several hundred micrometers, with the most commonly used thickness being 10-20 micrometers.

The film thickness of ordinary anodizing treatment is usually around 10-15 microns.

Blackening Treatment

Generally speaking, blackening treatment has a very small impact on the size of the workpiece, usually decreasing by 0.5-1 micrometers. However, please note that the impact on size may vary depending on the material and blackening treatment of different workpieces.

Electrochemical Polishing

The size change of the workpiece after electrochemical polishing varies due to factors such as material, polishing process, and workpiece shape.

Generally speaking, electrochemical polishing can slightly reduce the size of the workpiece, but the degree of reduction is usually at the micrometer level and requires precise measurement to detect.

In some cases, there may be some elastic deformation during the polishing process, and a slight increase in the size of the workpiece may be observed after polishing. But these changes are usually small and have little impact on the actual performance of the workpiece.

It should be noted that for some high-precision workpieces, such as precision mechanical parts, optical components, etc., the polishing process needs to be more precise and meticulous to avoid adverse effects of size changes on workpiece accuracy.