Bending is the most widely used metal forming process. It involves permanent plastic deformation of the sheet along a straight or curved line. Shanghai Yixing Technology is equipped with CNC bending machines and punching machines to realize the bending shape customers need.

Sheet metal bending is a metal processing technique used to transform flat sheet metal parts into V-shaped, U-shaped, or groove shaped shapes.

This is an important and convenient manufacturing process, as bending a flat metal plate into a new shape is much cheaper than machining V, U, or channel shapes from solid workpieces or casting in a foundry. In addition, the proportion of parts produced by bending is stronger when two flat metal sheets are welded into a V-shape.

Many types of sheet metal bending involve the use of machines called brakes, sometimes referred to as bending machines or sheet metal folding machines. Forces can be applied manually or using hydraulic devices for example.

Stretch bending: By applying external forces, the material is stretched and deformed along a certain radius of curvature to achieve a curved shape. This method is commonly used to manufacture curved parts, such as the sides and top covers of car bodies.

Bending: By applying pressure to a material, it undergoes plastic deformation at a certain point, thereby achieving bending at right angles or other angles. This is a common method for manufacturing right angle curved parts, such as steel structural beams and electrical cabinet frames.

Stretch bending: suitable for continuous curved surfaces and non right angle bending, especially when the length and curvature radius of the part are large.

Bending: suitable for manufacturing right angle bending parts of various angles, especially when the part size is small or high-precision bending is required.

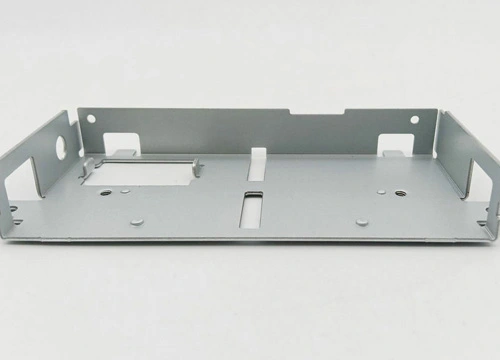

Below are some examples we have made. We can do the bending of angle steel, channel steel, I-beam, H-beam and others like square tube bending, round tube bending, aluminum profile bending etc.

The ease or difficulty of bending metal plates is influenced by several factors, such as mechanical properties, thickness, and the ability of the process/equipment used. Usually, materials with lower hardness and higher ductility are more prone to bending. We have a wide range of metal material can be chosen for sheet metal bending process.

Below is a brief summary of the material:

| Material | Grade |

| Carbon steel | S235, S345, SPCC, SPEC, CRS, HRS, DC01, SAPH440 etc |

| Aluminum alloys | AL5052, AL5754, AL6061, AL6063, AL1060 etc |

| Stainless steel | SS201, SS304, SS316, etc |

| Copper | C10100, C11000, C12200, GB/T1, T2, T3 etc |

| Brass | C27200, C36000, C37700, H63, HPb63-3, HPb59-1 etc |

| Cold or hot dip galvanized sheet | SGCC, SECC etc |

| ZINCALUME Steel | DC01+AZ150 |

| Titanium/Tin/Spring steel/Manganese steel etc | / |

As a professional Chinese sheet metal bending company, Shanghai Yixing Technology provides a wide range of sheet metal bending services. We can provide fast bending prototype in initial stage and also provide mass production in high speed with bending die.

Shanghai Yixing Technology provides professional sheet metal fabrication services. With rich experience in sheet metal bending, we can manufacture surprisingly complex forms with precision and repeatability. We use press brake or customized bending molds to accurately shape with minimal deformation and maximum consistency in a timely manner.

We have more than 10 different sheet metal bending equipment that can provide one-stop sheet metal bending services for any industry, while also providing high-quality products, fast turnover customer service, and on-time delivery. We are proud of this.

Listed below are the most common types of sheet metal bending:

1. Folding

Folding of metal plates, commonly known as stamping brakes, involves bending flat metal plates along a (usually) straight axis. This is a multifunctional method suitable for angles and angles/returns in metal plate shells.

2. Air bending

Air bending is a bending method in which the punch presses the metal plate into the mold, but not too far away so that it contacts the wall of the mold. This method is not as accurate as other methods, but it is very flexible: it can be used to make bends of V, U, and other shapes. This is partly because the geometric shape of the mold does not need to correspond exactly to the required sheet metal bending, as there is no contact between the two surfaces.

3. V bending

V-shaped mold bending is a forming process that involves bending a flat metal plate into a V-shaped mold in a press brake. This will create a precise and easily adjustable bend along the straight axis. V-shaped bending is a common process to make straight, oblique, or acute bends. Its bending angle is approximately 90 degrees. This bending shape is usually used to make structural components such as angle irons, pipes, and boxes.

1. Bending

Bending is a common technique in mechanical processing, which can bend materials such as plates and pipes into various shapes, such as arcs, angles, etc. In bending technology, the material type, thickness, and bending angle are important factors that need to be considered.

Meanwhile, attention should be paid to support and positioning during bending to ensure the stability and accuracy of the material during the bending process.

When processing different materials, it is necessary to adjust the process flow according to the characteristics of different materials to ensure the quality and efficiency of processing.

2. Forming

Forming refers to the technique of transforming materials into a certain shape through heating or pressure. Unlike bending technology, forming pays more attention to the shape changes of the material itself and requires the use of some special equipment to achieve. Forming technology mainly includes various types such as stamping, deep drawing, extrusion, forging, etc.

When using molding technology, special equipment is required to preheat, pre stretch, and other treatments on the material. Only when the materials are processed in an appropriate state can the processing quality be guaranteed.

Forming is much more complicated than bending process. And to a certain degree, we can say forming includes bending but bending cannot include forming.

Below is the minimum bend radius reference table which is based on theoretical sheet metal gauge thicknesses. Customers can consider this in the bending design.

Thickness of the sheet | Minimum bend radius |

1–6 mm | 1 time the thickness of the sheet |

6–12 mm | 1.5 times the thickness of the sheet |

12–25 mm | 2-3 times of the thickness of the sheet |