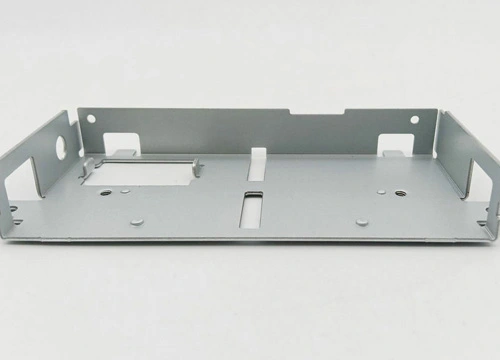

Material: DC01+Z120 /carbon steel /stainless steel /aluminum /copper /galvanized sheet available

Thickness: 1.2mm

Tolerance: ±0.1mm

Manufacturing process: sheet metal bending

Surface treatment: powder coating /painting /anodization /sandblasting /zinc coating etc available

Sheet metal bending, stamping, stainless steel bending, cabinet stamping

(1) Material selection: The performance and thickness of sheet metal materials vary, and the difficulty and requirements for bending forming also vary. Before bending, it is necessary to evaluate the mechanical properties, brittleness, etc. of the material to determine the bending plan and process flow.

(2) Mold design: Mold design is crucial for the accuracy and efficiency of sheet metal bending. The selection and manufacturing of molds should consider factors such as bending angle and bending radius, and it is necessary to simplify the structure of the mold as much as possible to improve production efficiency while meeting the requirements.

(3) Bending angle control: The accuracy of the bending angle determines the size and appearance of the finished product, and should be controlled within a reasonable range as much as possible. In actual production, precise angle control can be achieved using equipment such as CNC bending machines.

(1) Electronic product shell processing: With the popularization and development of electronic products, there is an increasing demand for shells with beautiful appearance and high precision requirements. Sheet metal bending technology can achieve the design and manufacturing of the shell shape while ensuring strength and stability, achieving a beautiful and durable effect.

(2) Automotive parts processing: As a modern means of transportation, automobiles have high requirements for safety and comfort in use. Sheet metal bending technology can provide more accurate dimensions and shapes in the manufacturing and processing of automotive components such as casings and chassis, ensuring the quality and performance of automotive components.

(1) Due to the limitations of material characteristics and production equipment, the control of bending angle and radius needs to be adjusted according to actual situations to avoid excessive stretching and deformation.

(2) The design and manufacturing of molds need to focus on accuracy and stability to avoid production failures and delays caused by mold damage or unreasonable design.

(3) Before bending, it is necessary to strictly test the quality and mechanical properties of the sheet metal material to avoid production accidents and quality issues caused by material issues.

As an important part of modern manufacturing, sheet metal bending technology has increasingly broad technical requirements and application scope. In actual production, it is necessary to pay attention to the requirements of material selection, mold design, and bending angle control to ensure the efficiency, accuracy, and stability of sheet metal bending processing.