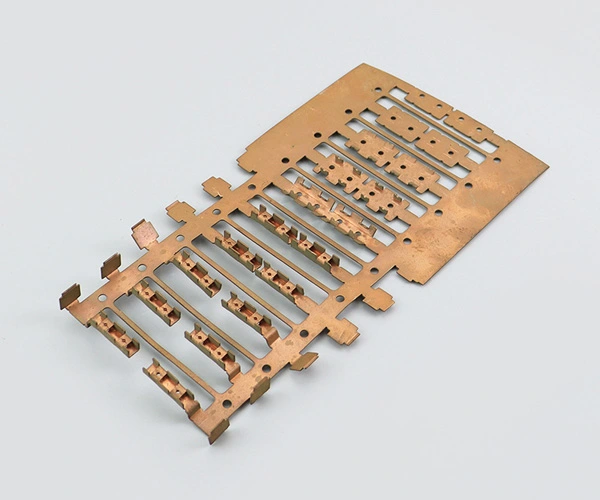

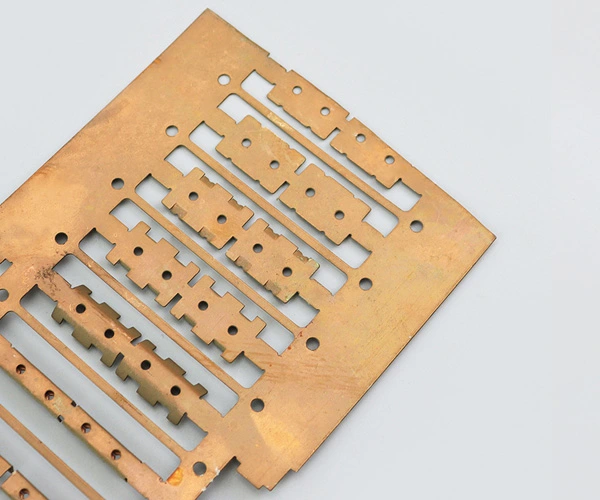

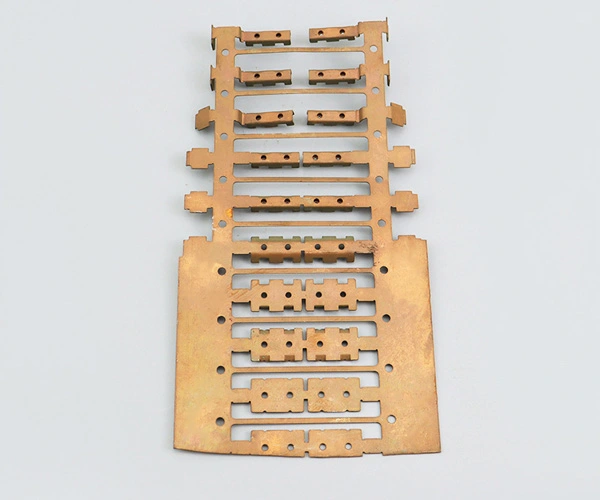

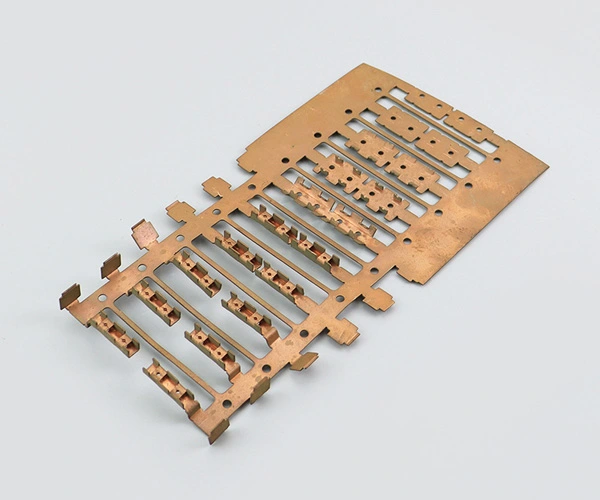

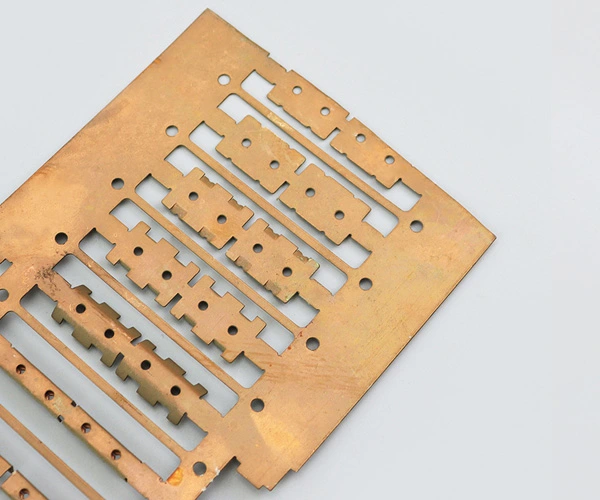

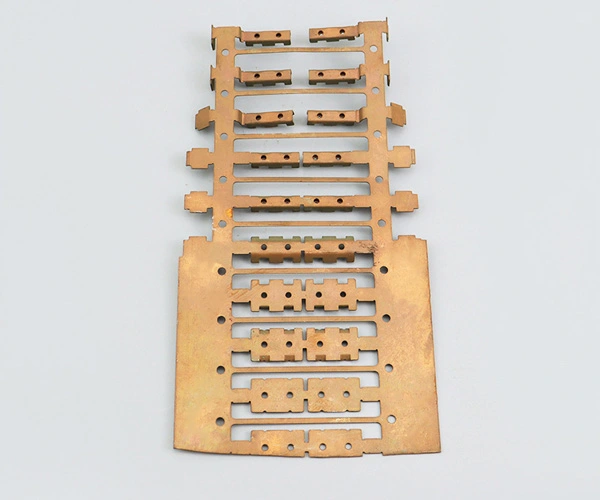

Material: Copper/Bronze

Surface: tin-plating/silver plating

Customized Size

Tolerance: ±0.05mm

sheet metal stamping, electrical terminals stamping by progressive die, stamping, punch stamping, metal process, fabricate metal

Progressive die refers to a stamping die composed of multiple workstations, each of which completes different processing, and each workstation is sequentially associated to complete a series of different Stamping processes in one stroke of the punching machine. Its function is to apply a certain form and magnitude of force on the sheet metal using convex and concave molds, causing plastic deformation of the material, thereby transforming the rough embryo into a product part. This high-efficiency tooling technology is widely adopted in china steel stamping to enhance productivity and consistency in mass production.

1. The progressive die is composed of three parts: the upper die, the lower die, and the mold sleeve, with the guide pillar as the guide.

2. The upper mold has an upper mold fixing plate, which is equipped with a convex mold and is connected to the upper mold with screws.

3. The lower mold is a fixed plate for the lower mold, which contains a core and is composed of other cores.

4. Install two semi conical concave molds into the concave mold sleeve with conical holes, with a cavity hole in the middle, and two semi circular concave molds with two positioning pins for positioning.

5. The unloading part is composed of a top rod and a top rod pad. After the part is formed, the upper mold is first pried open using a dedicated unloading work, and then the top rod is used to push the two semi conical concave molds out of the mold, allowing the mold to separate and take out the product.

If you are interested , please email us: contact@yxtechco.com