Anodic oxidation from Yixing Technology is the electrochemical oxidation of metals or alloys. The process in which aluminum and its alloys form an oxide film on aluminum products (anodes) under corresponding electrolytes and specific process conditions due to the action of applied current. Anodizing, unless otherwise specified, usually refers to sulfuric acid anodizing.

Yixing Technology's anodizing of aluminum alloys is quite common and can be applied in daily life. Due to the characteristics of this custom aluminum anodizing process, a hard protective layer is formed on the surface of aluminum parts, which can be used to produce daily necessities such as kitchenware.

1. Anti-corrosion Protection: Yixing Technology's Anodizing can form a dense and strong oxide layer on the aluminum surface, providing good corrosion resistance. This makes anodizing suitable for aluminum parts and products used in harsh environments, such as automotive parts, building materials, aerospace components, etc.

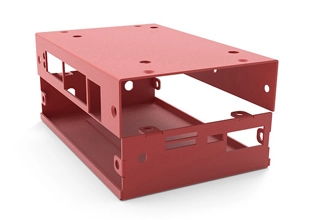

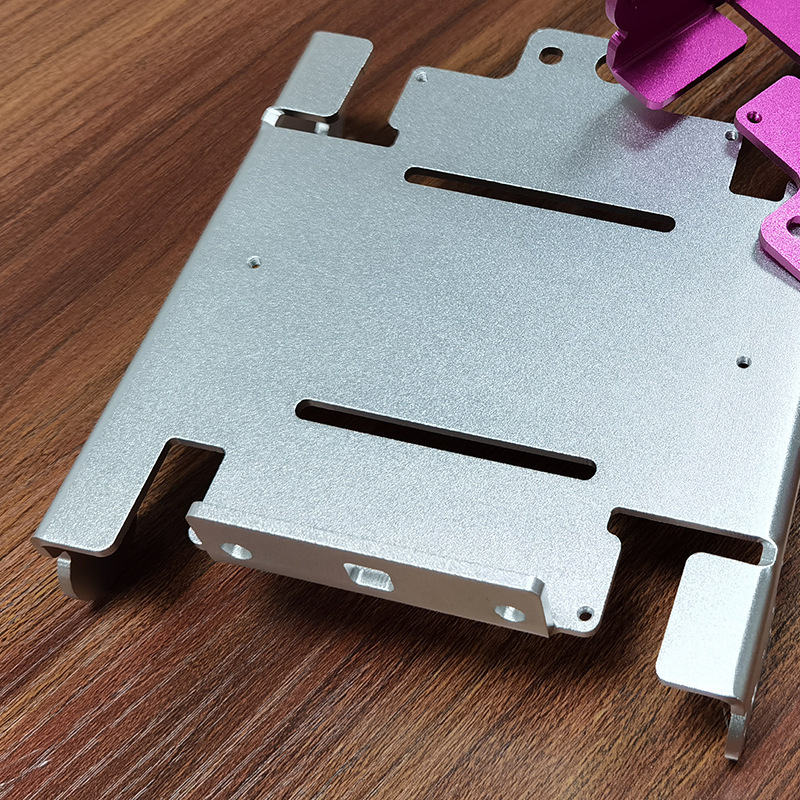

2. Decorative Effect: Anodizing treatment from Yixing Technology can form an oxide layer of various colors on the custom aluminum anodizing surface, providing a decorative effect. This makes anodizing widely used in indoor and outdoor architectural decoration, furniture, electronic product casings and other fields to increase the beauty and texture of the product.

3. Improved Insulation Properties: The oxide layer after anodization has high insulation properties and can be used in electronic and electrical applications, such as electronic radiators, electronic component housings, electrolytic capacitors, etc.

4. Improved Hardness: Anodizing treatment by Yixing Technology can significantly improve the surface hardness of aluminum. This makes anodizing suitable for applications requiring wear-resistant properties, such as automotive parts, motorcycle parts, industrial equipment, etc.

5. Dyeing and Printing: The surface of the oxide layer after anodization can interact with dyes and inks, which can realize dyeing and printing on the surface of aluminum materials. It is suitable for products that require custom aluminum anodizing processing such as logos, trademarks, patterns, etc.

As professional anodizing manufacturers, Shanghai Yixing Technology not only provide custom sheet metal parts for customers but also provide sheet metal surface treatment like anodization service for customers to meet their customized surface treatment requirements. There are multiple colors you can choose from natural, silver, black, gold, pearlescent silver, blue, red etc. There may be minimum order QTY for special color. You can send us pantone code or color template for us to match.