Cars are known as "machines that change the world". Due to its strong industrial correlation, the automotive industry is considered an important indicator of a country's economic development level. There are four major processes for automobiles, and Stamping technology is the top priority and also the top of the four processes.

1. Concept:

1. Stamping concept

Stamping is a forming and processing method that relies on a press and mold to apply external forces to plates, strips, pipes, and profiles, causing plastic deformation or separation, in order to obtain the required shape and size of workpieces (stamped parts). Stamping and forging belong to plastic processing (also known as pressure processing), collectively known as forging. The stamping blanks are mainly hot-rolled and cold-rolled steel plates and strips. 60% to 70% of the world's steel is made of sheet metal, most of which is stamped into finished products.

The body, chassis, fuel tank, radiator, boiler drum, container shell, iron core silicon steel sheets of motors and electrical appliances of automobiles are all stamped and processed. There are also a large number of stamping parts in products such as instruments, household appliances, bicycles, office machinery, and household utensils.

2. Characteristics of stamping process

A. Stamping is a processing method with high production efficiency and low material consumption. The stamping process is suitable for the production of large batches of parts and products, facilitating mechanization and automation, with high production efficiency. At the same time, stamping production not only strives to achieve less waste and no waste production, but also can be fully utilized even if there are leftover materials in certain situations.

B. The operation process is convenient and does not require the operator to have a high level of skill.

C. Stamped parts generally do not require further mechanical processing and have high dimensional accuracy.

D. Stamped parts have good interchangeability. The stamping process has good stability, and the same batch of stamping parts can be interchanged and used without affecting assembly and product performance.

E. Due to the use of sheet metal as the material for stamping parts, their surface quality is good, providing convenient conditions for subsequent surface treatment processes such as electroplating and painting.

F. Stamping processing can obtain parts with high strength, high stiffness, and light weight.

G. The cost of mass produced stamping parts using molds is low.

H. Stamping can produce complex shaped parts that are difficult to machine using other metal processing methods.

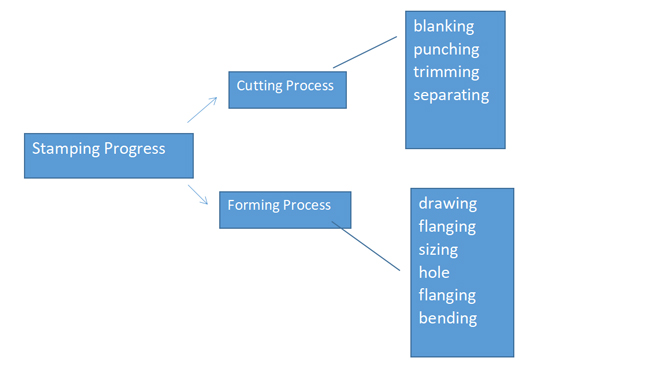

3. Introduction to stamping process

The mechanical steering system uses the driver's physical strength as the source of steering power, and all mechanical transmission structures are mechanical. The mechanical steering system consists of three main parts: steering control mechanism, steering gear, and steering transmission mechanism.

A. Separation process:

The finished and semi-finished products with a certain shape, size, and cross-sectional quality are obtained by separating the sheet material along a certain contour line under external forces. Separation condition: The stress inside the deformed material exceeds the strength limit σ B.

a. Blanking

Use a punch to cut along a closed curve, with the lower part being the part. Used for manufacturing flat parts of various shapes.

b. Punching

Use a punch to cut along a closed curve, and the lower part is waste material. There are several forms of punching, such as forward punching, side punching, and hanging punching.

c. Trimming

Trim the edges of the formed parts neatly or cut them into a certain shape.

d. Separation

Use a die to cut along an unclosed curve to produce separation.

When forming left and right parts together, the separation process is more commonly used.

B. Forming process:

The billet undergoes plastic deformation without rupture to obtain finished and semi-finished products of a certain shape and size.

Forming condition: yield strength σ S

a. Stretching

Forming blank sheets into various open hollow parts.

b. Flanging

Form a vertical edge of the sheet or semi-finished product along a certain curve and curvature.

c. Sizing

The forming method used to improve the dimensional accuracy of formed parts or obtain small fillet radii.

d. Flipping hole

Make vertical edges on pre punched or semi-finished plates or unpunched plates.

e. Bending

Bending the sheet metal into various shapes along a straight line can process extremely complex parts.

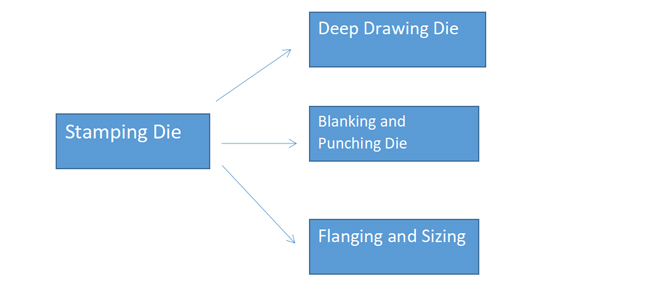

2: Stamping mold:

Molds are known in Japan as the "driving force for entering a wealthy society" and in Germany as the "emperor of the metal processing industry". The level of mold design and manufacturing technology is one of the important indicators to measure the level of product manufacturing in a country.

A. Mold classification

According to its working principle, it can be divided into:

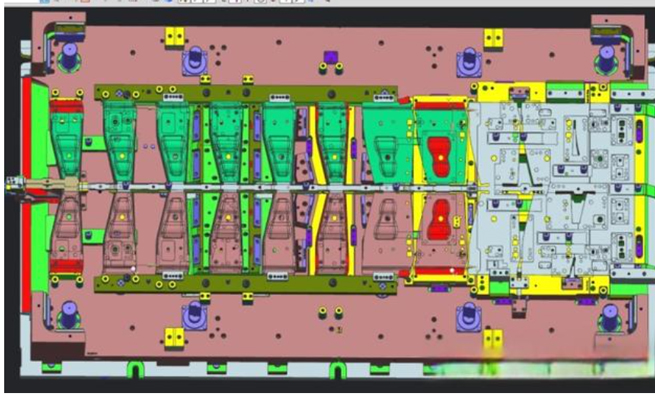

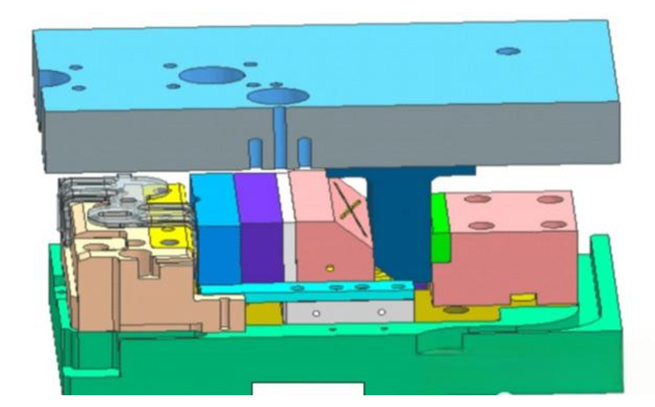

B. Basic structure of the mold

Stamping dies are usually composed of two parts: upper and lower molds (convex and concave molds)

Composition: 1 working part, 2 guidance, 3 positioning, 4 limit, 5 elastic components, 6 lifting and flipping

3: Stamping equipment:

1. Press

A. According to the structure of the bed, press machines can be divided into two types: open press and closed press.

The open press has three open sides, and the bed is C-shaped, with poor rigidity. It is generally used for small presses;

The front and rear sides of the closed press are open, and the bed is closed, with good rigidity. It is generally used for large and medium-sized presses. B. According to the type of driving slider force, press machines can be divided into: mechanical press and hydraulic press

2. Unwinding line

3. Plate cutting machine

The cutting machine is mainly used to cut straight edges of various sizes of metal sheets.

There are two types of transmission: mechanical and hydraulic. 4: Stamping material:

Stamping materials are important factors that affect the quality of parts and the lifespan of molds. At present, stamping materials not only include low-carbon steel, but also stainless steel, aluminum and aluminum alloys, copper and copper alloys, etc.

Steel plate is currently the most widely used raw material in automotive stamping. With the requirement of lightweight body, new materials such as high-strength steel plate and sandwich steel plate are increasingly used in automotive body.

1. Performance requirements for steel plates

A. Has good mechanical properties and significant deformation ability.

The mechanical properties of metal materials refer to tensile strength, yield strength, elongation, hardness, and plastic strain ratio.

High plastic strain ratio r value (anisotropic performance)

High work hardening exponent n;

High elongation δ;

Low yield to strength ratio( σ S/ σ b);

Low aging index.

B. Good surface quality

The surface of the steel plate shall not have obvious defects such as scabs, cracks, inclusions, and scratches. The interior panels of the vehicle body are allowed to have defects that do not affect formability and paint adhesion, such as small bubbles, scratches, roller marks, minor scratches, and slight oxidation colors; The outer panel must meet the quality level of FD (O5), that is, the better side of both sides must not have any defects, that is, it cannot affect the appearance quality after painting or electroplating, and the other side should meet the requirements of FB (O3).

2. Classification of steel plates

A. Divided by thickness: thick plate (above 4mm), medium plate (3-4mm), and thin plate (below 3mm)

The stamping parts of car bodies are mainly made of thin plates:

B. Classified by rolling status: hot-rolled steel plate, cold-rolled steel plate

Hot rolling is the process of softening an alloy at a temperature higher than its recrystallization temperature, and then using a compression wheel to compress the material into thin sheets or cross sections of steel billets, causing the material to deform without changing its physical properties. Hot rolled plates have poor toughness and surface smoothness, resulting in lower prices. Hot rolling is relatively rough and cannot produce very thin steel.

Cold rolling is the process of further rolling a material that has undergone the hot rolling, pitting and oxidation removal processes at a temperature lower than the recrystallization temperature of the alloy using a roller to allow the material to undergo recrystallization. After repeated cold pressing recrystallization annealing cold pressing (2-3 cycles), the metal in the material undergoes molecular level changes (recrystallization), resulting in changes in the physical properties of the alloy. Therefore, its surface quality is good, its smoothness is high, and its product size accuracy is high. The performance and organization of the product can meet some special usage requirements.

Cold rolled steel plates mainly include: cold rolled carbon steel plates, cold rolled low-carbon steel plates, cold rolled steel plates for stamping, high-strength cold rolled steel plates, etc.

Cold rolled carbon steel plate

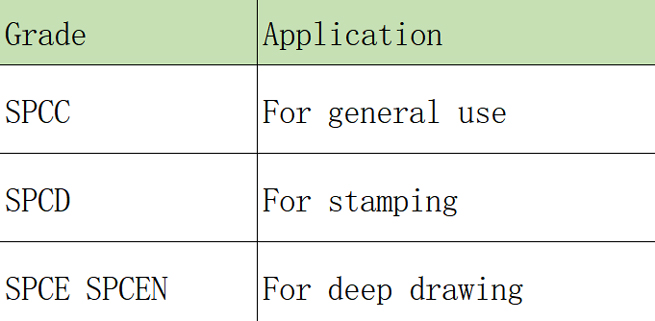

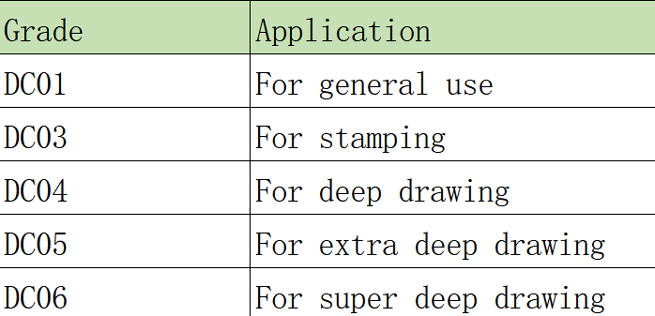

S is the abbreviation for Steel, P is the abbreviation for Plate, the third letter C is the abbreviation for Cold, and N represents the need to ensure non aging.

Cold rolled low-carbon steel plate

5: Inspection tools:

A gauge is a specialized inspection equipment used to measure and evaluate the dimensional quality of parts.

In automotive manufacturing, whether for large stamping parts, interior parts, welded sub assemblies with complex spatial geometric shapes, or for simple small stamping parts, interior parts, etc., specialized inspection tools are often used as the main detection method to control product quality between processes.

The inspection tool has the advantages of being fast, accurate, intuitive, and convenient, especially suitable for the needs of large-scale production.

The inspection tool often consists of three parts:

① Skeleton and base parts;

② Body part;

③ Functional components (including quick chucks, positioning pins, detection pins, mobile gap sliders, measuring meters, profile cards, etc.).