In metal fabrication, spinning, stamping, and deep drawing are three common forming processes, each with unique advantages and applications. Below is a detailed comparison in terms of cost, process characteristics, production efficiency, and product suitability to help customers select the optimal solution.

| Process | Principle | Applicable Materials | Typical Products |

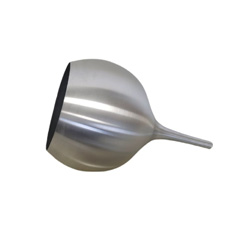

| Spinning | Rotating metal sheet + roller pressure forming | Soft metals (aluminum, copper, stainless steel) | Lamp shades, cookware, hemispheres, cones |

| Stamping | Die-based cutting/bending/shallow drawing | Thin sheet metals (aluminum, steel, etc.) | Electronic enclosures, automotive parts, hardware |

| Deep Drawing | Multi-step deep forming (annealing required) | Ductile metals (aluminum, steel, copper) | Cans, cups, deep-cavity containers |

|  |  |

| Metal Spinning | Metal Spinning | Stamping |

(1) Cost Analysis

| Cost Factor | Metal Spinning | Stamping | Deep Drawing |

| Tooling Cost | Low (simple mandrel) | High (precision dies) | Medium (multi-stage dies) |

| Per-Unit Cost | Medium (small batches) | Low (economies of scale) | Medium (annealing required) |

| Material Utilization | High (low waste) | Medium (nesting possible) | Low (trimming waste) |

Small batch/customized: Custom metal spinning is most cost-effective (minimal tooling).

Mass production: Stamping offers the best economy (tooling cost amortized).

Deep-cavity parts: Deep drawing from reliable deep drawing suppliers is moderate in cost but requires annealing.

|  |  |

| Metal Spinning | Deep Drawing | Stamping |

(2) Process Characteristics

| Feature | Mteal Spinning | Stamping | Deep Drawing |

| Part Complexity | High (freeform surfaces) | Medium (structural parts) | Low (deep cavities) |

| Material Thickness | Medium (≤12mm) | Thin (≤6mm) | Thin (≤5mm) |

| Tolerance Control | Medium (skill-dependent) | High (die precision) | Medium (multi-step errors) |

Advantages:

Spinning: Ideal for complex curves & axisymmetric parts(e.g., lighting shades, architectural domes)

Stamping: High precision & efficiency for standardized parts.

Deep Drawing: Specialized for deep cavities (e.g., battery cases, beverage cans).

|  |  |

| Metal Spinning | Deep Drawing | Stamping |

(3) Production Efficiency

| Metric | Metal Spinning | Stamping | Deep Drawing |

| Production Speed | Slow (single-piece) | Very fast (progressive dies) | Medium (annealing needed) |

| Tooling Change Time | Short (roller adjustment) | Long (die replacement) | Medium (multi-stage) |

| Optimal Batch Size | Small-medium batches | Mass production | Medium-large batches |

Production Recommendations:

<100 pcs: Spinning (quick setup, low tooling cost).

>10,000 pcs: Stamping (high-speed press advantage).

500-5,000 pcs (deep cavities): Deep drawing (balances speed & cost).

At Yixing Technology, We specialize in metal spinning, stamping, and deep drawing, offering flexible solutions:

Spinning: Custom lighting, high-end cookware, complex shapes.

Stamping: Automotive/electronic parts (precision progressive dies supported).

Deep Drawing: Medical containers, industrial cans.

Workflow:

Provide drawings/samples → 2. Process evaluation (cost + lead time) → 3. Recommend optimal solution → 4. Production & delivery.

Need case-specific advice? Contact our engineering team!