The photovoltaic brackets, poles, frames of solar photovoltaic panels, combiner boxes, boost equipment, distribution boxes/cabinets (high-voltage AC cabinets, low-voltage AC cabinets, DC cabinets), photovoltaic inverters, photovoltaic charging piles, grid connected cabinets, energy storage battery boxes, control cabinets, data storage cabinets, servers, etc. in photovoltaic modules use a large number of sheet metal structural components.

The sheet metal part in photovoltaic modules should be designed reasonably, with a small volume as much as possible, good heat dissipation, high processing accuracy, and strong sealing. When working in harsh outdoor environments, the cabinet and battery frame should not deform, be damaged, or rust during their lifespan. This poses high requirements for the cabinet design, cutting, bending, spraying, and assembly of sheet metal factories.

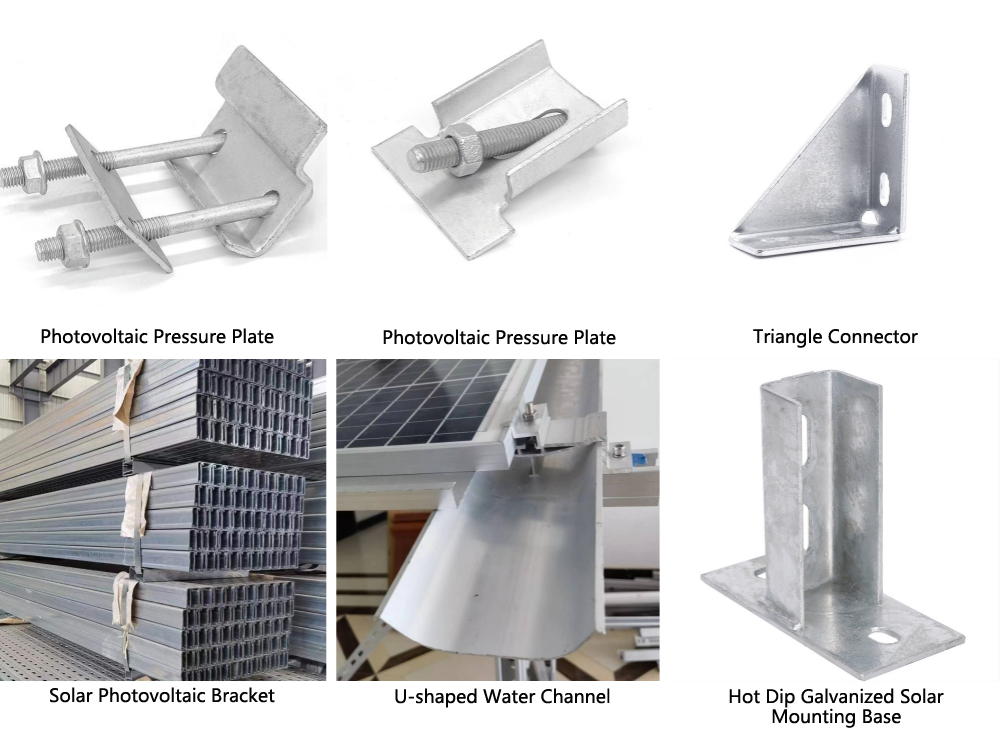

Solar photovoltaic bracket is a special bracket designed for placing, installing, and fixing solar panels in a solar photovoltaic power generation system. At present, solar photovoltaic brackets are divided into three types in terms of materials: concrete brackets, steel brackets-Hot dip galvanizing, and aluminum alloy brackets.

1. Concrete support: mainly used in large photovoltaic power stations, due to its heavy weight, it can only be placed in the wild and in areas with good foundations, but it has high stability and can support large-sized battery panels.

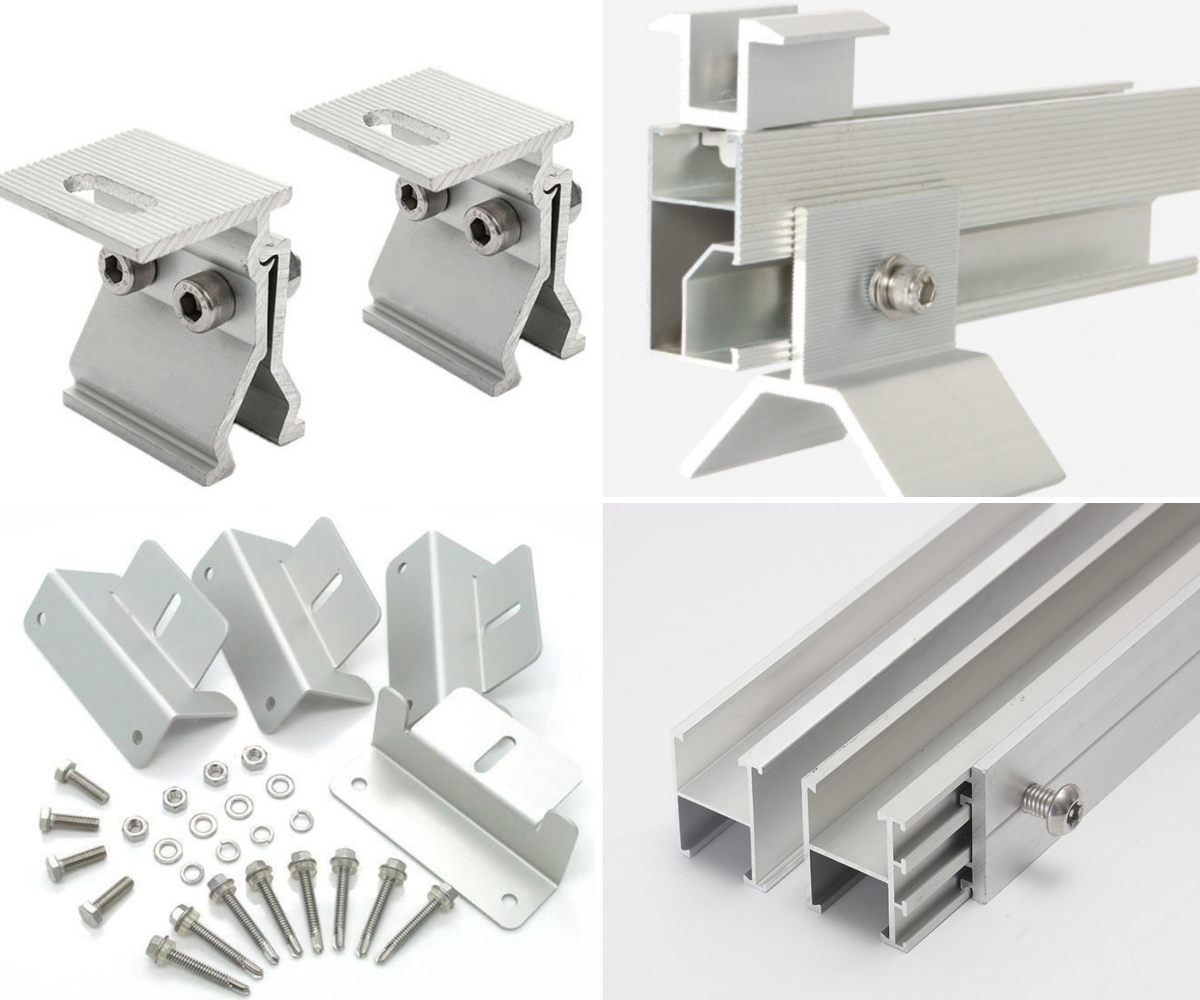

2. Aluminum alloy bracket: generally used in solar energy applications on roofs of civil buildings. Aluminum alloy has the characteristics of corrosion resistance, light weight, aesthetics, and durability, but its self bearing capacity is low and cannot be applied in solar power plant projects. In addition, the price of aluminum alloy is slightly higher than that of hot-dip galvanized steel.

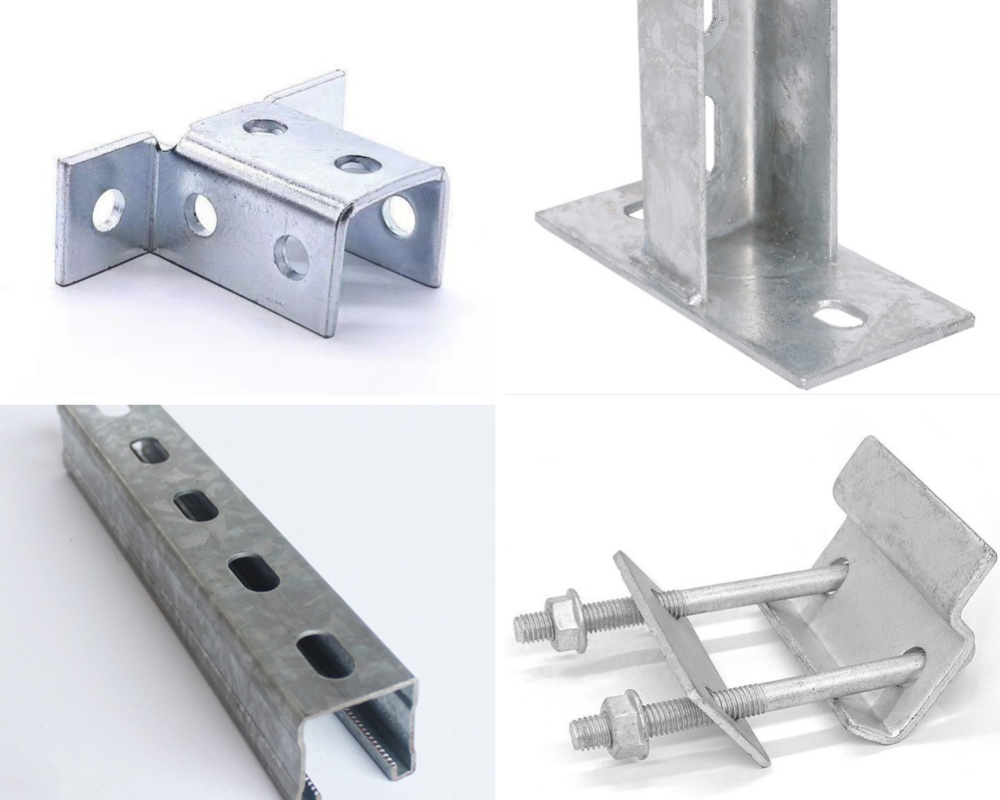

3. Steel bracket-Hot dip galvanizing: Stable performance, mature manufacturing process, high bearing capacity, easy installation, widely used in civil, industrial solar photovoltaic and solar power stations. Among them, the section steel is produced by the factory, with unified specifications, stable performance, excellent corrosion resistance, and beautiful appearance.

It is worth mentioning that the combination steel support system only requires the use of specially designed connectors to assemble the channel steel for on-site installation, with fast construction speed and no need for welding, thus ensuring the integrity of the anti-corrosion layer. The disadvantage of this product is that the connection process is complex, there are many types, and high requirements for production, manufacturing, and design, so the price is not cheap.

In order to maximize the power output of the entire photovoltaic power generation system, combined with the geographical, climatic, and solar resource conditions of the construction site, the solar modules are fixed in a certain orientation, arrangement, and spacing of the support structure, usually steel structure and aluminum alloy structure, or a combination of the two.

As a professional sheet metal fabrication factory, Shanghai Yixing manufactures all kinds of solar mounting components based on customers’ drawings. Basically it can be divided into three manufacturing processes. Feel feel to send us drawings for cost analysis.

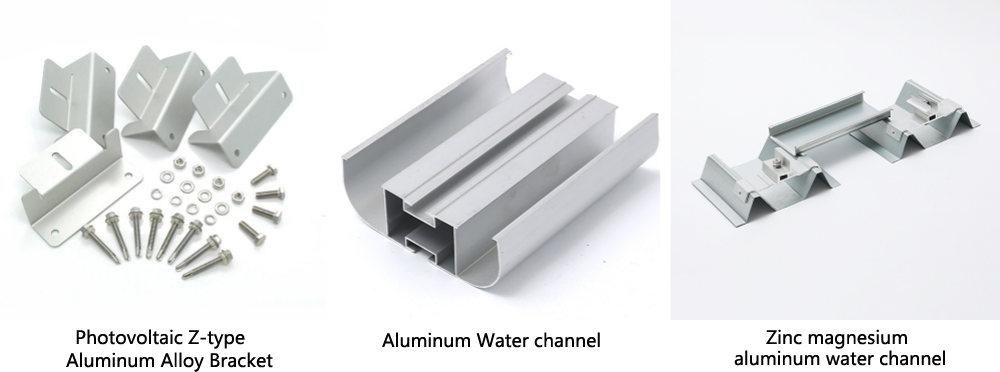

1. Aluminum extrusion, drilling, cutting, anodization

This process is widely used for aluminum mounting parts like solar end clamp, middle clamp, rail clamp, rail connector, Thin Film Double-glazed Module Clamp etc. Below are some examples we have made.

2. Metal bending, stamping, welding, hot-dip galvanizing

Many mounting solar base, brackets, frames, rails are made by bending, stamping and welding process. Yixing is equipped with bending machines, stamping machines and welding machines to complete the product production. hot-dip galvanizing is usually done on steel material for anti-rust property.

3. Cutting, rolling, welding and hot-dip galvanizing

Photovoltaic spiral ground piles are widely used in the installation of photovoltaic energy. Yixing manufactures various spiral ground piles per customers drawings. Strong strength, great anti corrosion performance and high durability is the quality we aim to reach.

As a sheet metal factory in China, we have strong engineer team and quality control system to control every process of the production. From in coming material inspection, in process control to final inspection, every inspection will be recorded and tracked.

With 20 years experience in sheet metal manufacturing like laser cutting, sheet metal bending, metal stamping, deep drawing, welding etc, Shanghai Yixing Technology can handle all the sheet metal work from easy to complex with best price and quality. We produce sheet metal parts for distribution boxes/cabinets, battery box, solar support, frames etc in solar energy industry for many years and have won the praise from customers around the world.

Photovoltaic sheet metal refers to the manufacturing process of metal products and parts used in photovoltaic power generation systems, which usually need to have characteristics such as high precision, high strength, and high corrosion resistance.

Cutting: Use equipment such as shearing machines or laser cutting machines to cut metal sheets or coils into the required size and shape, providing raw materials for subsequent processing.

Forming: Using equipment such as bending machines, punches, or presses to shape metal sheets or coils into the desired shape and size to meet the needs of photovoltaic power generation systems.

Welding: Using welding equipment to weld metal sheets or coils to achieve the required strength and stability.

Surface treatment: Surface treatment of metal products or parts, such as spraying, powder coating, etc., to improve their corrosion resistance and aesthetics.

Assembly: Assembling multiple metal products or parts together to obtain a complete photovoltaic sheet metal product.

In the process of photovoltaic sheet metal processing, it is necessary to choose appropriate processing methods and equipment, and strictly control quality and safety to ensure the reliability and performance stability of the products. At the same time, it is also necessary to pay attention to environmental protection and resource utilization, minimize waste and energy consumption, and achieve sustainable development.