Deep drawing is the cornerstone of manufacturing, completely changing the way we produce complex metal components. With the development of industry, the importance of this technology is increasing day by day, so professionals and enthusiasts must master its subtle differences. Do you know? More than 40% of all metal products we use in daily life are manufactured by deep drawing and Stamping processes, which fully demonstrates the widespread popularity and efficiency of deep drawing and Stamping processes.

Deep drawing and stamping is a metal forming process that utilizes a series of molds to radially pull metal sheet blanks into the forming mold through a punch, forming a three-dimensional shape. This technology is particularly suitable for producing complex and high-precision metal parts, while other methods may encounter difficulties.

Desire to gain a deeper understanding? Please join us and we will unveil the mystery of deep drawing, introduce the process and advantages of deep drawing, and answer the hottest questions surrounding this key manufacturing method.

01

What is deep drawing and stamping?

Deep drawing and stamping is a specialized metal forming process that transforms flat metal sheets (usually referred to as billets) into deep and hollow shapes, also known as "stretching" parts. Standard stamping usually shapes the metal without significantly changing the depth of the metal, while deep drawing stamping is different in that it focuses on manufacturing parts with a depth greater than the diameter.

Process flow

Starting from the blank: This process starts with a flat metal plate and is selected based on the required final product specifications.

Stretch metal: A punch presses the metal plate into the mold cavity, forming the metal into the desired shape. This may need to be carried out in several stages, each of which involves drawing the metal deeper to bring it closer to the final shape.

Re-stretching: For particularly deep parts, the metal can be re stretched through a series of molds, gradually forming without affecting its integrity.

Common materials

Deep drawing and stamping are widely used and can be carried out on various metals. The most commonly used materials include:

Stainless steel: Known for its corrosion resistance and strength.

Aluminum: Lightweight and highly ductile, making it an ideal material for complex shapes.

Carbon steel: balancing durability and plasticity.

Copper: Known for its excellent conductivity, commonly used in electrical components.

Brass: Often selected for its aesthetic and corrosion resistance.

The selection of materials usually depends on the intended use of the finished product, as each metal has its unique properties and may have advantages in specific situations.

02

Advantages of deep drawing and stamping

Although deep drawing and stamping is a technological process, it has many advantages and is the preferred choice for many manufacturers. Here are some of its outstanding advantages:

High cost-effectiveness: One of the most eye-catching advantages of deep drawing and stamping is its cost-effectiveness. By using a series of progressive molds in a single operation, manufacturers can quickly produce a large number of parts, reducing labor costs and waste. Over time, this will greatly save costs, especially when producing large quantities of orders.

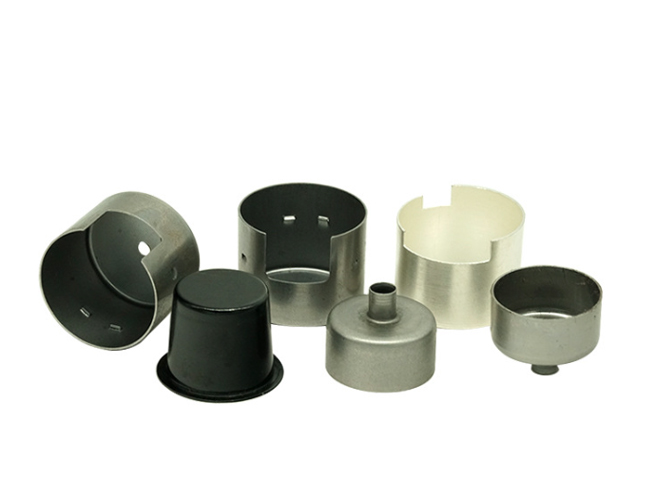

Produce versatility in various shapes: Deep drawing is not limited to simple or standard shapes. Its craftsmanship allows for the creation of complex and intricate designs that may be challenging or even impossible to achieve using other methods. Whether your goal is cylindrical, conical, rectangular, or any other unique shape, deep drawing and stamping technology can meet your needs.

High quality surface treatment: The nature of the deep drawing and stamping process ensures that the finished parts have a smooth and high-quality surface finish. Metal is stretched and compressed, rather than cut or joined, which means there are no seams, rough edges, or irregular areas. This not only enhances the beauty of the product, but also ensures its durability and functionality.

Integrating deep drawing technology into the manufacturing process can produce high-quality products, reduce production costs, and have an advantage over competitors who still rely on more traditional and inefficient methods.

03

Common applications of deep drawing

Deep drawing stamping has the ability to produce complex and durable parts, which can be applied to multiple industries. Its versatility and efficiency make it the preferred method to meet various manufacturing needs.

Industries that frequently use this method:

Automotive industry: Deep drawing and stamping play a crucial role in the production of parts such as fuel tanks, mufflers, and various engine components.

Aerospace industry: Aircraft casings, engine components, and other critical components are often produced using this method due to their precision and durability.

Medical: Surgical instruments, medical equipment casings, and implantable components typically rely on deep drawing due to its high precision and ability to be compatible with biocompatible metals.

Electronic products: Battery casings, metal casings of electronic devices, and connectors are all applications of deep drawing technology.

Household appliances: From cookware to washing machine drums, many household items benefit from deep drawing and stamping processes.

Examples of products manufactured using deep drawing and stamping processes:

Beverage can: The cylindrical and smooth surface of the beverage can is achieved through deep drawing and stamping technology.

Cooking pots: The deep seamless structure of many cooking pots is the result of this method.

Fire extinguisher casing: The sturdy and durable seamless casing of the fire extinguisher is usually manufactured using a deep drawing and stamping process.

Camera metal casing: Many protective metal casings of cameras and photography equipment are made using this process.

Spray can: the familiar shape and design of spray can is the direct result of deep drawing and stamping.

The widespread application of deep drawing and stamping technology in various industries has proven its efficiency, versatility, and consistent high quality.

04

The Challenge of Deep Drawing and Stamping

Although deep drawing stamping has many advantages, like other manufacturing processes, it also faces a series of challenges. Recognizing these challenges and implementing effective solutions is crucial for maintaining efficiency and product quality.

Potential issues during processing:

Wrinkling: When the metal plate is pulled into the mold, it sometimes wrinkles, especially in the flange area.

Tearing: If the metal is stretched too thin during the drawing process, tearing will occur.

Rebound: After metal forming, it may attempt to restore its original shape, resulting in inaccurate dimensions.

Surface defects: If the metal plate has unnecessary contact with other surfaces, scratches, marks, or defects may appear.

Material differences: Differences in material properties can lead to inconsistencies in the final product.

Solutions and best practices to overcome these challenges:

Optimize mold design: Carefully designed molds can minimize wrinkling and tearing. It is necessary to ensure that the mold radius and blank clamping force reach the optimal state.

Lubrication: Proper lubrication can reduce friction, prevent surface defects, and ensure a smoother stretching process.

Material selection: Choosing the correct material with consistent performance is crucial. Pre testing the consistency of materials helps to obtain consistent results.

Slowing down the drawing speed: Reducing the drawing speed helps prevent tearing, especially for metals with strong plasticity.

Post processing: Annealing and other processes help reduce the impact of rebound and ensure that the metal maintains the desired shape.

By understanding these challenges and implementing recommended solutions, manufacturers can ensure that the deep drawing and stamping process is as efficient and error free as possible.

05

Comparison between Deep Drawing Stamping and Other Stamping Methods

Stamping is a major category of metal forming, and deep drawing stamping is one of its professional branches. When comparing deep drawing stamping with other stamping methods, it is necessary to understand their unique advantages and potential disadvantages.

Advantages of deep drawing and stamping

Complex shapes: Deep drawing and stamping are adept at producing intricate, deep, and complex shapes, which may be challenging for other methods.

High material efficiency: This method usually reduces waste, as the metal is formed by stretching rather than cutting.

Seamless components: The produced parts are seamless, which can enhance their strength and aesthetics.

Consistency: With the correct settings, deep drawing and stamping can produce a large number of consistent high-quality parts.

Disadvantages of deep drawing and stamping

Initial setup cost: This process requires specialized molds, and the initial production cost may be high.

Material limitations: Not all metals are suitable for deep drawing and stamping, which limits the range of materials available.

Depth limitation: Although deep drawing is very suitable for manufacturing deep shaped parts, there are limitations to the depth of the stretched part without defects.

When to choose deep drawing instead of other methods

Depth requirement: If the required depth of the part is greater than half the diameter, deep drawing and stamping is usually the preferred choice.

Material saving: For projects that prioritize material saving, the efficiency of deep drawing and stamping in reducing waste makes it the first choice.

Seamless structure: If the final product requires a seamless structure, such as certain containers or cylinders, deep drawing and stamping technology is the best choice.

Mass production: For large-scale production with extremely high consistency requirements, the repeatability of deep drawing and stamping is a major advantage.

In summary, although the deep drawing stamping process has many advantages, it is necessary to evaluate the specific requirements of the project to determine whether it is the most suitable method or whether other stamping techniques are more suitable.

06

Conclusion

Deep drawing and stamping is a witness to the development of manufacturing processes, which integrates efficiency, precision, and versatility. It can produce complex and seamless parts and has become an indispensable tool in various industries, from automobiles to electronics. As we delve deeper into its subtle differences, advantages, and applications, the significance of understanding this method has become very apparent. It not only shapes the products we use daily, but also shapes the future development trajectory of the entire manufacturing industry.

Looking ahead, we cannot help but ponder: with the rapid development of technology and materials science, how will deep drawing technology develop in the next decade? What role will deep drawing and stamping play in shaping the next generation of products in our constantly evolving world?