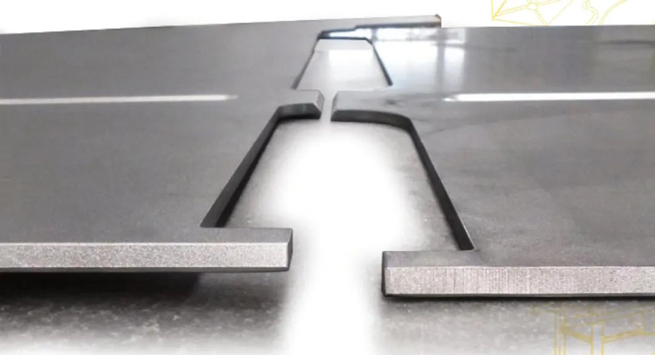

As shown in Figure 1, the left part shows rebound deformation and is not completely flat, while the right part is leveled by a part leveling machine. Flat and stress free parts can improve the production efficiency of Bending and welding, ensuring customer satisfaction.

The metal sheets delivered to the sheet metal factory appear sufficiently flat. But appearances can be deceiving, especially for metal materials. Materials or parts that appear flat may become uneven during processing due to processing stress.

So it is meaningful and necessary to understand what happened before the raw materials were sent to the sheet metal factory. The raw material of the sheet material comes from the rolled coil material. At the metal processing service center, these coils are uncoiled, straightened, and finally cut into a certain length. Although the sheet appears flat, there is still stress inside (which is clearly present in the metallographic structure of the material).

When thermal cutting (such as laser or plasma cutting machines) these materials, stress is released and the parts become uneven. This situation can occur in both thin and thick metal parts.

This situation also applies to black and non-ferrous metal parts. The use of auxiliary gases plays a significant role in the process of cutting such parts. For example, when oxygen is used to cut carbon steel, it undergoes an exothermic reaction with the metal. This will introduce a large amount of heat into the cutting area, causing the cutting process to occur quickly (the byproduct of this chemical reaction is the oxidized edge, which needs to be cleaned for painting). However, the additional heat will also release more stress in the metal. Compared to oxygen, using inert gas nitrogen cutting can reduce heat input, but even with milder processes, stress is still being released.

The stress is released and the parts become uneven, which is particularly troublesome for production workshops using new Laser cutting technology, as certain parts may tilt or bounce on the fence during Laser cutting, resulting in collision and damage to the cutting head. Especially when the cutting speed reaches 30m/min or greater, and the acceleration exceeds 2m/s2, it has become an industry standard. A very expensive component on laser cutting equipment may be damaged by parts on the cutting machine that rebound due to stress.

Any cutting process can release the stress generated during the coiling process. This stress can be clearly seen in the rebound phenomenon of the metal after cutting or punching (punching can cause the material to form work hardening and generate new stress, which can be seen on the punched parts).

How does a sheet metal factory deal with the stress generated by metal materials during the coiling process, as well as the stress released by part materials after being cut or stamped? A part leveling machine can provide assistance. Part leveling machines can provide necessary flat parts for sheet metal factories and their downstream manufacturing processes, ensuring higher production efficiency and reducing scrap during Bending and welding processes.

The part leveling machine (Figure 2) achieves flatness by applying repeated bending forces to the metal sheet or part through a set of leveling rollers. The leveling roller exerts pressure on the metal material as it passes through the leveling machine. The stress intensity applied to metal materials will decrease and ultimately eliminate their internal stress.

Figure 2 Leveling Roller and Electromechanical Leveling System of Part Leveling Machine

How are these leveling rollers arranged? This depends on the type of metal material, material thickness, and the flatness to be achieved. The variables of the part leveling machine include: the number of leveling rollers; Center distance of leveling roller; Layout and support method of leveling rollers; The stiffness of the leveling roller frame and the entire machine; The support of the leveling roller (length and layout of the support roller); Leveling gap control system and its ability to maintain stable gaps; Electricity consumption.

Convenience of cleaning leveling and support rollers, as well as maintaining the machine. While extending the metal, the leveling roller gradually reduces pressure and flattens the parts; The leveling roller frame outside the machine tool can be driven by an electric motor. The size of the corresponding part to be leveled, and the leveling pressure depends on the diameter of the leveling roller. The diameter of each leveling roller is combined with the position of the leveling roller, the design of the machine roller frame, support roller, and frame, and there is a corresponding operation display window. Generally speaking, smaller straightening roller diameters are used for thinner materials, while larger roller diameters are used for thicker materials. Leveling machines can usually level parts with thicknesses ranging from 0.2mm to nearly 70mm.

The flatness accuracy provided by leveling actually varies depending on the application of metal materials and their thickness and type. For example, metal parts used in the manufacturing of cranes and mining equipment are considered very good if the leveling machine can provide flatness ranging from 0.5mm/m to 1mm/m. However, for saw blade manufacturers who require a flatness of 0.1mm/m or higher, this flatness is not suitable. Fortunately, a high-precision part leveling machine can provide flat parts for heavy-duty equipment manufacturers and also produce parts with higher tolerances for saw blade manufacturers.

The leveling of parts can also be very meticulous. For example, manufacturing companies in the aerospace industry typically use aluminum materials. 5mm is considered a relatively thick component for these companies, but for mining equipment manufacturers, this thickness is too thin. This type of aluminum material usually undergoes heat treatment to achieve higher strength. After heat treatment, the aluminum material becomes soft and is stored at a temperature of -18 ° C. If such parts are immediately leveled after punching, the part leveling machine must face two main challenges. Firstly, the material is soft, so the flattening roller must be gentle when squeezing and extending the material to avoid material deformation. Secondly, when frozen parts come into contact with high ambient temperatures, condensation water will form on the surface of the parts. Therefore, the components of the leveling machine should be made of stainless steel or coated steel to prevent corrosion.

The results of part leveling machine production are very simple - flat parts, but they are actually complex machines that can handle difficult to correct material deformation.

For example, punching and heat treatment materials. Both materials often exhibit intermediate wave deformation or edge wave deformation. Correcting such parts or plates requires special measures and techniques.

For (some) punched plates and heat treated materials, the advanced leveling roller bending control function can specifically increase the leveling pressure in certain areas of the part or plate, while reducing the leveling pressure in other areas. Through this controlled leveling method, the material is extended in the required longitudinal direction, thereby reducing or even eliminating intermediate wave deformation and edge wave deformation.

High tensile strength materials are another type of material that is difficult to handle. Processing such materials requires a high-power machine that combines very large diameter leveling rollers with corresponding roller spacing to reduce material stress and provide good flatness. Eliminate intermediate wave deformation and edge wave deformation.

Any advanced manufacturing equipment requires a dedicated operator, who is experienced and more importantly, a curious operator who can bring truly different results. If he is willing to spend time adjusting and testing parts to achieve good leveling effects, the factory can achieve efficient leveling of parts and higher quality products in downstream manufacturing processes.

In theory, leveling is a simple and easy operation. In addition to the speed of the leveling roller, the operator only needs to adjust two other parameters: the leveling gap between the inlet and outlet, and the angle at which the parts are fed into the machine. By finding the correct combination, the operator can optimize the leveling results.

Of course, the built-in computing tools in the device control system will also provide assistance. After inputting thickness, yield strength, and material type, the control system will output the recommended leveling parameters. Usually, these parameters can already ensure good leveling results. If the operator wants to seek better leveling results, this set of leveling parameters can be used as the basic parameters for him to start adjusting.

Part leveling can help sheet metal factories increase production and productivity. The report data provided by the sheet metal factory indicates that incorporating a part leveling machine into their production process resulted in a productivity increase of approximately 25% in the bending process after the parts were leveled. Flat parts are bent more accurately, which means less rework and stronger product quality consistency. In the welding department, this means that the assembly fixtures can be greatly simplified, improving assembly accuracy, and welding employees will be happy. The significant reduction of non-conforming products has improved production efficiency.

This is particularly true for robot welding. Tighter and more consistent welds mean using fewer filler wires, smoother welding production lines, and faster automated processes.

Parts leveling machines can also create new business opportunities for a company. For example, if a company wants to serve customers in the construction industry, the ceiling and facade they provide must be absolutely flat, and each sheet must be equally flat, as any sheet that does not meet the specifications may cause installation work to stop.