1. Maintenance during mold installation

(1) Before installing the mold, clean the upper and lower surfaces of the mold to ensure that the mold mounting surface and the press work surface are not crushed, and that the upper and lower mounting surfaces of the mold are parallel during production.

(2) After the mold is installed, open the mold and clean all parts of the mold, especially the guide mechanism. For surface molds, clean the surface to ensure the quality of the parts. Lubricate each sliding part of the mold and apply grease. Inspection of all parts of the mold, especially safety parts, such as: safety side pins, safety screws, side guards, punching waste channels, etc.

2. Maintenance during production

(1) During production, oil the corresponding parts of the mold regularly, such as: the pressing ring and fillet of the drawing mold; the knife edge of the trimming mold; the flanging knife block, etc.

(2) Regularly clean the waste material from the small hole waste channel of the trimming and punching die.

3. Post-production maintenance

(1) After production, a comprehensive inspection of the mold must be carried out.

(2) Clean the mold comprehensively to ensure the cleanliness of the mold.

(3) Clean the waste material in the mold to ensure that there is no waste material in the waste box.

(4) Feedback the usage status and post-use situation of the mold truthfully to the mold subpoena.

This maintenance work is completed by mold repair personnel, and records are kept according to the maintenance status. The following describes the requirements and methods of secondary warranty for different parts:

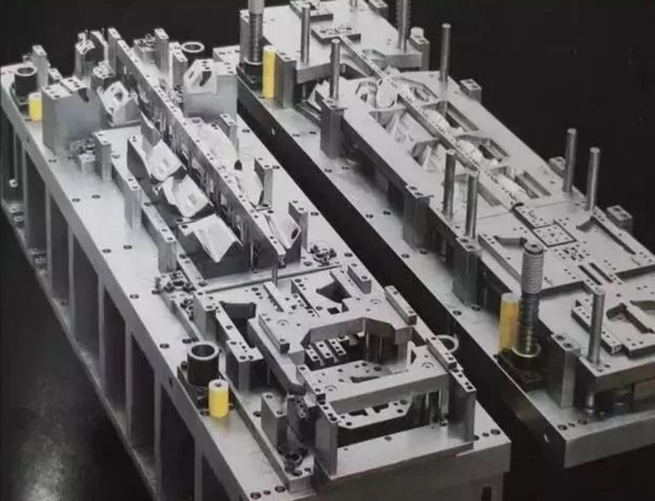

1. Drawing die punch and die

The main problems with the convex and concave dies of drawing dies are roughening and pitting of the profile. During maintenance, the rounded corners of the mold are mainly polished. If a pressure pit occurs, the mold must be repaired and then repaired.

2. Guide parts (guide posts, guide sleeves, guide plates, etc.)

The mold will have pull marks and other phenomena during work. The main reasons include dirty lubricating oil and uneven guide clearance. If there are pull marks on the guide parts, they can be eliminated by pushing them with a whetstone and then polishing them.

3. Trimming knife edge

During the use of the mold, the cutting edge is prone to chipping and edge collapse. At this time, the damaged blade of the mold needs to be repaired and welded.

4. Spring and other elastic parts

During use, the spring is one of the most vulnerable parts of the mold and often breaks and deforms. The solution is to replace it. However, during the replacement process, you must pay attention to the specifications and models of the springs. The specifications and models of the springs are determined by color, outer diameter, and length. They can only be replaced if these three items are the same. This consistency is especially important in synchronized operations, such as those performed by compound and progressive dies, where spring performance affects multiple stations simultaneously.

5. Punch and punch sleeve

Most of the punches and punch sleeves used on the mold are standard parts. During the use of the mold, the punch is prone to breakage, Bending and gnawing. The punch sleeves are usually chewed up. Damage to the punch and punch bushings is generally replaced with parts of the same specification. The parameters of the punch mainly include working part size, installation part size, length size, etc.

6. Fastening parts

Check whether the fastening parts are loose or damaged. The solution is to find parts with the same specifications for replacement.

Visual monitoring of stamping molds can effectively detect whether the material belt of the continuous stamping mold is delivered in place, whether blockage and stacking of materials occur, etc. It can effectively reduce the number of stamping molds, protect the stamping mold, reduce costs and increase efficiency, and improve the level of factory automation; at the same time, it can also monitor the stamping process Conduct timely monitoring of appearance defects on parts.