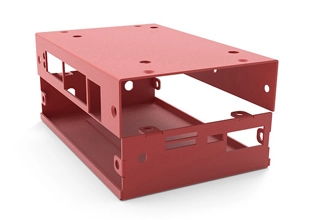

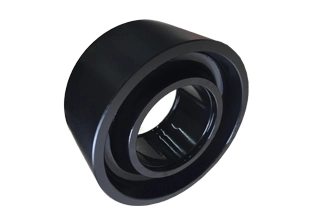

Sheet metal surface treatment enhances aesthetics and durability, involving processes like powder coating, anodizing, plating, and painting. These treatments improve corrosion resistance, increase surface hardness, and provide a desired finish, extending the material’s lifespan and visual appeal.