Because of its excellent characteristics and perfect efficiency, cold Stamping is very common in products in our daily life, and it is also very good in machining. Because Stamping parts do not need to go through conventional processing such as turning, milling, and grinding, it is more convenient and faster, and a very stable product can be obtained.

The current mold industry is not very optimistic. Regarding mold cost control, every quotation for mold orders is very careful. In order to solve your doubts, we summarize some common mold quotation principles for you.

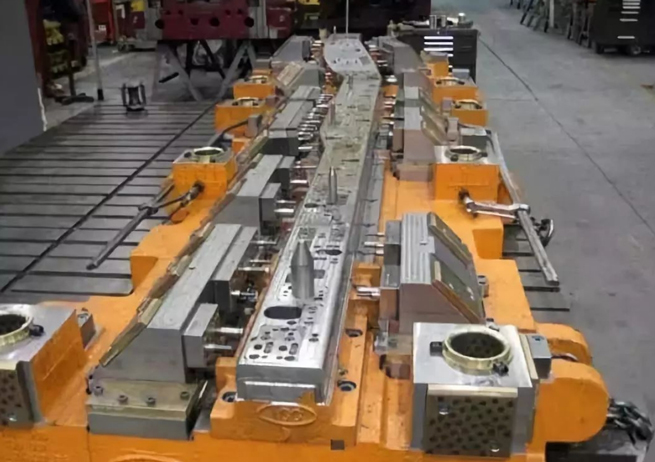

Raw material cost: Template material is one of the most important costs for each set of molds. Because domestic materials are not up to standard, many imported materials are used, especially for the punches and cutting edges of the mold. All good materials require post-process "heat treatment" ".

Post-process "heat treatment" cost: There are currently two common mold heat treatments: ordinary heat treatment and vacuum treatment, and the costs of these two heat treatments are very different.

Ordinary heat treatment: Most of them are for large materials, and the requirements for the material itself are not high. However, this kind of heat treatment is cheap, calculated by weight, about 11 yuan/kg.

Vacuum heat treatment: Just the opposite of the ordinary type, it is basically used for small materials, the material itself has high requirements, the effect is good, and it is not easy to deform, but it is relatively expensive.

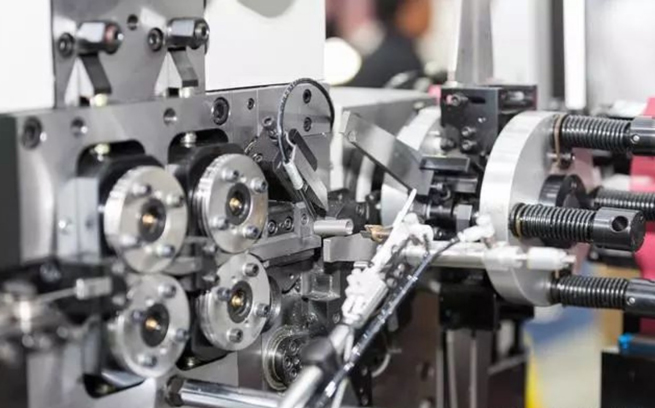

Precision processing cost: Precision processing basically refers to wire cutting. In mold machining, wire cutting costs account for a large proportion. And the calculation method is mostly based on area. According to the efficiency of wire cutting and different machine models: fast wire is about 0.0045---0.005 yuan per square millimeter. Slow wire costs 0.02 yuan per square millimeter. Slow wire processing is generally used only when precision is required.

Cost of mold standard parts: Common standard parts in molds can be roughly classified into three categories: springs, guide posts, guide bushes, and screws. The springs among them can be divided into five colors according to their colors: yellow, blue, red, green, and tea, and their elasticity increases in sequence.

Labor cost: This is an uncertain value. Generally speaking, the salary is generally between 150-250 yuan per day, ranging from 150 to 250 yuan per day.

Other costs: Probably include trial mold costs, sample material costs, machine mold repair costs, mold design costs, management costs, etc.

Profit: For skilled molds, the profit is about 30 to 40 percent of the total cost of the above, depending on the actual situation.

Because the products are different, the quotations cannot be the same and require careful analysis. In addition to the above costs, we also need to analyze the following details:

What material and thickness are the designed products made of?

Whether the tolerance requirements of the product are strict, and what grade the output belongs to.

The structural complexity of the product and the structural and processing accuracy requirements of the mold.

The amount of spare parts required for wearing parts and the after-sales service cycle time.

Where is the proofing done? And the demand for the finished product quantity after proofing.

It is necessary to conduct a thorough investigation of the stamping machine tools in the customer's company to understand the technical parameters of the other party's equipment to facilitate design.

Although the above details are not very costly, they may be insignificant individually. However, no detail can be overlooked in our quotation, and all must be taken into consideration. In order to make an accurate quotation, you must master the specific parameters of each link without making any mistakes. This is related to whether the mold being connected can be profitable and how much profit it can make.