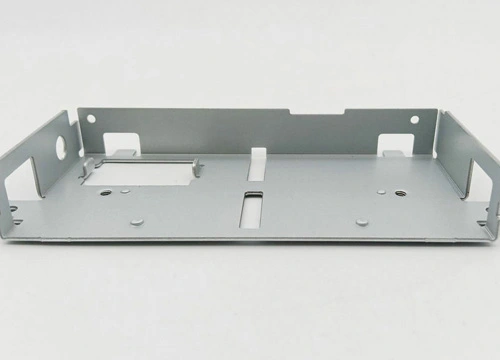

Material: stainless steel SS201 /SS304 /SS316 carbon steel /stainless steel /aluminum /copper /galvanized sheet available

Thickness: 0.8mm

Tolerance: ±0.1mm

Manufacturing process: sheet metal bending

Surface treatment: powder coating /painting /anodization /sandblasting /zinc coating etc available

Sheet metal bending, stamping, stainless steel bending, cabinet stamping

1. The bending edge of the board is not straight, and the size varies.

Reason: The pressing force provided by the equipment is insufficient; The height dimension is too low; There is no pre-bending or wire pressing process in the process flow; The rounded corners of the concave convex mold are asymmetric or the bending force is uneven.

Solution: Increase the pressing force; The height cannot be lower than the smaller size; Add pre bending or wire pressing processes; Ensure that the rounded corners of the concave convex mold are smooth and symmetrical, with consistent gaps.

2. There are scratches on the surface of the bent plate.

Reason: The surface of the raw materials themselves is rough; The bending gap is too small; The radius of convex mold bending is too small.

Method: Increase the smoothness of the concave convex mold; Change the bending gap; Increase the bending radius of the convex mold.

3. Cracks are generated at the bending corners.

Reason: The bending radius is too small; The grain pattern and bending curve direction of the board are the same; The burrs on the board face outward; Metal itself has low plasticity.

Method: Increase the bending radius of the mold; Adjusting the layout during material cutting; Adjust the burrs within the rounded corners; Switch to high softness sheet or anneal.

4. Hole deformation caused by bending.

Reason: Due to friction between the outer surface of the bending arm and the concave mold, tension is generated, and elastic bending is used, resulting in deformation of the positioning hole.

Method: Increase the pressure on the top plate; Add dotted lines on the top plate to increase the friction between the two; Use shape bending.

5. The bending part of the board becomes thinner.

Reason: The gap between the concave and convex molds is too small; The rounded corners of the concave mold are too small.

Method: Adjust the gap between the concave and convex molds; Increase the fillet radius of the concave mold.