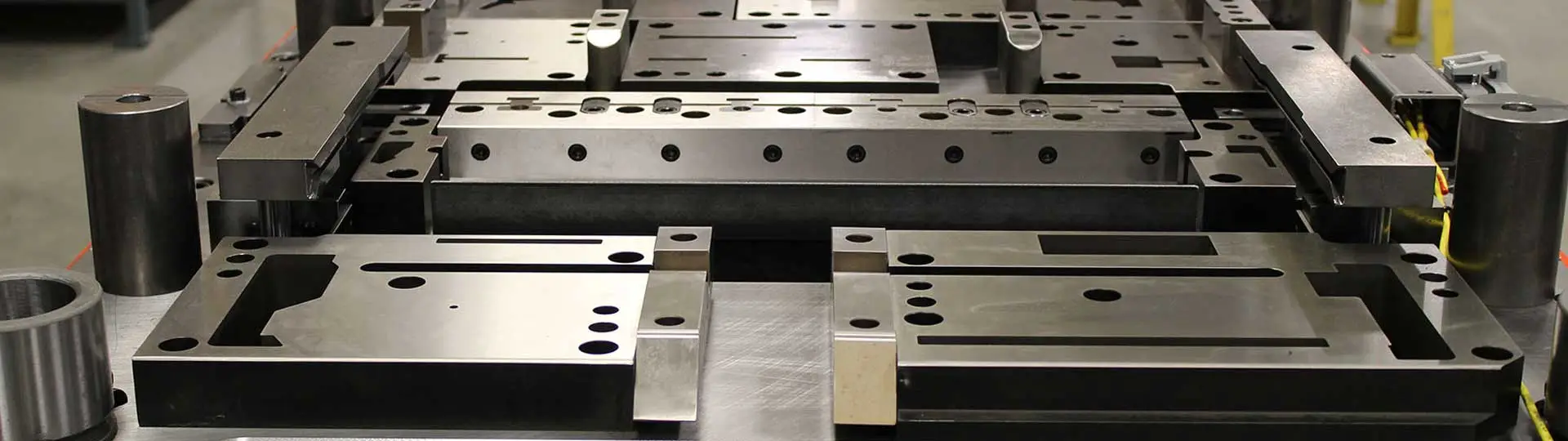

Compound die stamping is a good choice for medium and big size part and also lower mold cost compared with progressive die stamping. Shanghai Yixing provides multiple stamping choice including compound die stamping to satisfy customers’ different demands.

Compound Die Stamping is a stamping process similar to progressive die stamping, but the difference is that progressive dies have many orderly arranged cavities on the mold, and the material will be formed by different cavities after being formed by the mold. Finally, we can obtain a complete product.

However, compound dies combine two or more feature forming modules with multiple sliders and mechanical settings. In a stamping cycle, different details of the parts will be generated, such as cutting blanks, stamping, stretching concave convex shapes, and deep drawing forming.

Although it appears that the mold made a movement, the clever mechanical transmission principle enables all functions to be completed at once and maintains extremely strong quality stability.

Composite stamping dies are very suitable for production orders with limited budgets and small to medium-sized batches, and can demonstrate very high efficiency and low labor costs, making them a competitive manufacturing technology in the market.

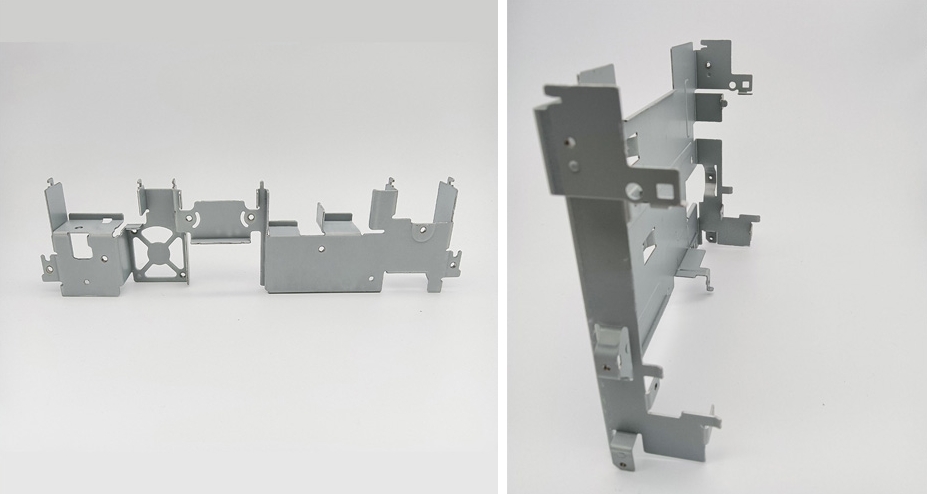

Compound die stamping uses various metals and alloys to produce high-performance parts with extraordinary precision and repeatability. When selecting metal materials for stamping parts, it is important to consider their compatibility with the metal stamping process and your application.

Below is the short summary of the compound die stamping material you can choose from:

| Material | Grade |

| Carbon steel | S235, S345, SPCC, SPEC, CRS, HRS, DC01, SAPH440 etc |

| Aluminum alloys | AL5052, AL5754, AL6061, AL6063, AL1060 etc |

| Stainless steel | SS201, SS304, SS316, etc |

| Copper | C10100, C11000, C12200, GB/T1, T2, T3 etc |

| Brass | C27200, C36000, C37700, H63, HPb63-3, HPb59-1 etc |

| Cold or hot dip galvanized sheet | SGCC, SECC etc |

| ZINCALUME Steel | DC01+AZ150 |

| Titanium/Tin/Spring steel/Manganese steel etc | / |

At Shanghai Yixing Technology, we have a professional compound die stamping production line with 10 high-speed punches ranging from 40 tons to 630 tons. All equipment is dedicated to running compound dies. We have a professional stamping technology team that can meet the needs of metal stamping parts in various industries.

Compound die stamping is suitable for small and medium sized metal stamping parts. It not only ensures the precision tolerances required for part design, but also has lower manufacturing costs than progressive molds. If you don't know whether progressive die or compound die is more suitable for your project, contact with us and our engineer can help to determine which is the best for projects.

Shanghai Yixing Technology provides professional sheet metal fabrication services. We offer a wide range of precision stamping solutions, including mold design and manufacturing, DFM manufacturability report, fast prototype production, product mass production, other value-added service like welding, surface treatment, heat treatment, packaging, and transportation to various parts of the world.

1) Compound die: A mold structure in which a punching machine completes multiple processes such as material cutting and punching in one stroke.

2) Progressive die: composed of multiple workstations, each of which is sequentially associated to complete different processing tasks. A series of different stamping processes are completed in one stroke of the punching machine.

(1) Compound mold:

1) The workpiece has good coaxiality, a flat surface, and high dimensional accuracy.

2) High production efficiency, not limited by the accuracy of plate shape and size. Sometimes waste corners can also be used for replication.

3) The processing and manufacturing of mold parts is difficult and costly. Stamping and concave molds are easily limited by small wall thickness and are not suitable for certain lower parts with small inner hole spacing and inner hole and edge spacing.

(2) Progressive mold:

1) Progressive die is a type of multi task continuous punching die. In a mold, it can include many processes such as cutting, bending, and deep drawing, with high productivity.

2) Progressive mold operation is more safe.

3) Easy to automate.

4) High speed punching machines can be used for production.

5) It can reduce the area of stamping machines and sites, as well as the transportation of semi-finished products and warehouse occupancy.

6) Parts with high size requirements should not be produced using progressive molds.

Compound Die Stamping is widely used due to their high cost-effectiveness. More and more small and medium-sized enterprises and project purchasers choose to use compound dies to complete their projects.

Unlike traditional single punch die (different manufacturing processes require constant mold replacement), compound die can perform multiple different processes within a stamping cycle to maintain stable quality, reduce errors caused by continuous operation of parts, and reduce mold costs. The upper part is much smaller than similar progressive molds.

1. Compound die cost is cheaper than a progressive die cost.

2. Producing simple and small parts is both fast and efficient.

3. High repeatability of single mold cases.

4. A single stroke will produce a flatter part.

1. Not suitable for metal geometries with high complexity.

2. Not suitable for small size part in large quantities.

3. Production speed is not as fast as progressive die.