Mold material: Cr12MoV、SKD11、DC53

Mold cavity: 1

Customized Size

Mold life: 1000000 PCS

Certificate:ISO9001:2008

Inspection: IQC, IPQC,FQC,QA

Package: Carton, Foam(standard export packing), Logo Printing, Wood Box, Special Requirement is welcome.

Progressive Die for Metal Clamp, Progressive Die for Auto Parts, Progressive Die for Electrical Terminals and Contacts, Progressive Die for Metal Hardware

The core of progressive die stamping is to integrate multiple stamping processes into one die. The material (usually coil or strip) is gradually fed into the die through an automatic feeding device. Each station completes a process (such as hole punching, bending, stretching, forming, etc.), and finally the separation or forming of the parts is completed at the last station.

*High efficiency, suitable for mass production

Metal clamps are widely used in industries such as industry, automobiles, and electronics, so the demand is very large. Progressive die stamping can complete multiple processes at one time, with high production efficiency and fast speed, and is suitable for mass production of metal clips and fixtures.

*High precision, ensuring parts consistency

The design of the progressive die is very precise. The guide device ensures that the upper and lower dies are accurately aligned, which can well control the dimensional consistency of the product. The shape and dimensional accuracy requirements of the metal clamp can be fully achieved through the progressive die.

*High material utilization, reducing costs

The progressive die can reduce waste by optimizing the layout design, improve the material utilization of the metal clamp, and reduce the material cost of the clamp.

*High degree of automation, reducing labor costs

The progressive die is usually combined with an automatic feeding device and a robot manipulator. Fully automated production not only improves production efficiency, but also reduces labor costs and human errors.

*Strong ability to form complex shapes

The design structure of metal clamps usually requires cutting, stamping, bending, forming and other processes, and these processes can be completed in one go through the multi-station design of the progressive die, reducing subsequent processing steps.

There are many types of clamps we can make, including Spring Clamp, C-Clamp, U-Clamp, Snap Clip, Hinge Clamp, Pipe Clamp, Quick-Release Clamp, Magnetic Clamp, etc. We can not only make large quantities of clamps through continuous molds, but also meet small batch needs through simple molds, single punch dies, etc. Some special clamps are a combination of sheet metal production and casting production. We can provide one-stop service. Sheet metal stamping, die casting, casting, forging and machining can be perfectly combined to provide customers with comprehensive processing, assembly and surface treatment services.

Spring Clamp

C-Clamp

U-Clamp

Snap Clip

Hinge Clamp

Pipe Clamp

Quick-Release Clamp

Magnetic Clamp

Tool steels are widely used in progressive and general stamping dies because of their excellent hardness, wear resistance, toughness and heat resistance. The choice of tool steel depends on the specific application, production volume and the material being stamped. The following are the most suitable tool steels for progressive and general stamping dies:

| Tool Steel | Hardness (HRC) | Key Properties | Applications |

| D2 / SKD11 | 60-62 | High wear resistance, moderate toughness | High-volume progressive dies, precision dies |

| A2 / SKD12 | 58-60 | Good toughness, wear resistance | Medium-duty progressive dies, stamping dies |

| O1 | 58-62 | Good machinability, wear resistance | Low-to-medium volume stamping dies |

| M2 / SKH51 | 62-64 | High hardness, heat resistance | High-speed progressive dies, thick materials |

| S7 | 58 | High toughness, shock resistance | High-impact progressive dies, heavy-duty dies |

| H13 / SKD61 | 54 | Heat resistance, thermal fatigue | High-temperature progressive dies, hot forming |

| Vanadis 4 Extra | 60-62 | High wear resistance, toughness | High-performance progressive dies |

| CPM 10V | 60-62 | Extreme wear resistance | High-abrasion progressive dies |

| P20 / 1.2311 | 28-32 (pre-hard) | Good machinability, surface harden | Prototype dies, low-volume stamping dies |

The most common materials for metal clamps include carbon steel, stainless steel, aluminum, brass, and copper. The choice of material depends on the specific application requirements, such as strength, corrosion resistance, weight, and cost. For specialized applications, materials like titanium or plastics may also be used.

| Material | Key Properties | Applications | Grade |

| Carbon Steel | High strength, low cost | General-purpose clamps, industrial use | AISI 1018, AISI 1045 etc |

| Stainless Steel | Corrosion resistance, durability | Marine, chemical, food processing, medical | AISI 304 (most common), AISI 316 (higher corrosion resistance) etc |

| Aluminum | Lightweight, corrosion resistance | Aerospace, automotive, lightweight clamps | 6061-T6, 7075-T6 etc |

| Brass | Corrosion resistance, non-magnetic | Electrical, plumbing, decorative clamps | C36000 (free-cutting brass) etc |

| Copper | Electrical/thermal conductivity | Electrical clamps, heat exchangers | C11000 (electrolytic tough pitch copper) etc |

| Titanium | High strength-to-weight ratio | Aerospace, medical, high-performance clamps | Grade 5 (Ti-6Al-4V) etc |

| Cast Iron | High compressive strength | Heavy-duty industrial clamps | Gray cast iron, ductile iron etc |

1) Analyze the Clamp Drawing

When we get the metal clamp drawing from the customer, we will first review the material and thickness on the drawing. And then annual usage. The annual usage determines whether we need to use a progressive die to do this project, because the cost of a progressive die is much more expensive than a regular die. Small quantities are not suitable for progressive die stamping. Then carefully analyze the clamp features (holes, bends, screws, slots, etc.) to clarify the key dimensions and tolerances.

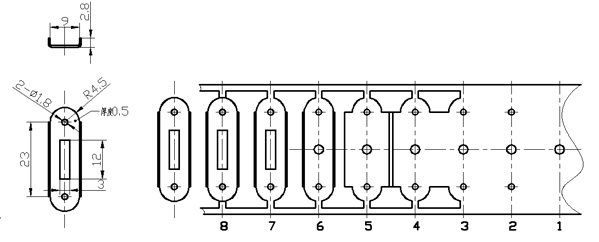

2) Design the Strip Layout

We first determine the size of the sheet used to produce the clamp, arrange multiple clamps on the sheet to reduce material waste, and subdivide the production process of the clamp into: punching, bending, forming, etc., and design each step of the process at the specific station of the continuous mold.

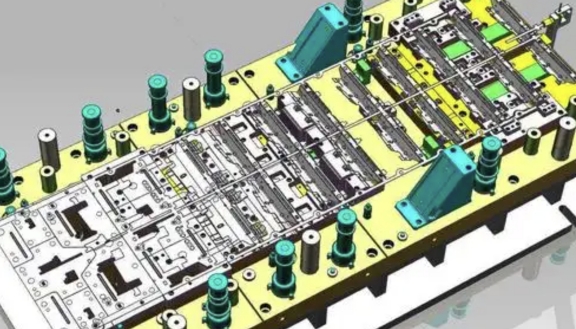

3) Design the Progressive Die

We use CAD/CAM software to design each station on the mold for different operation like station 1 piercing, station 2 bending, station 3 forming etc. Also need to design punches, dies and other components and select suitable for material for die such as D2 tool steel for high wear resistance.

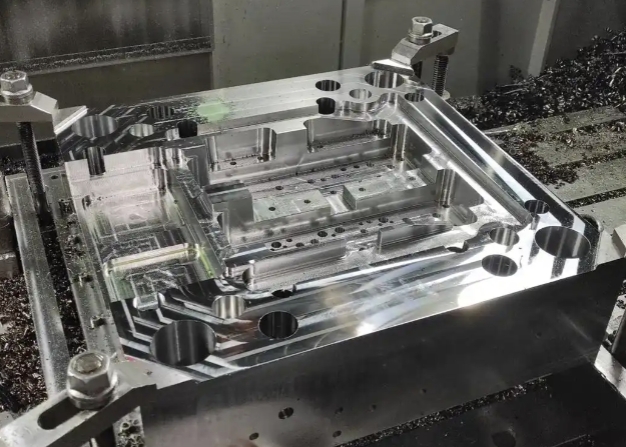

4) Fabricate the Progressive Die

We use CNC machining, EDM and other processes to produce mold components, and then assemble the upper plate, lower plate, male die, female die, guide system, positioning system, ejection system and other components to make a complete progressive mold.

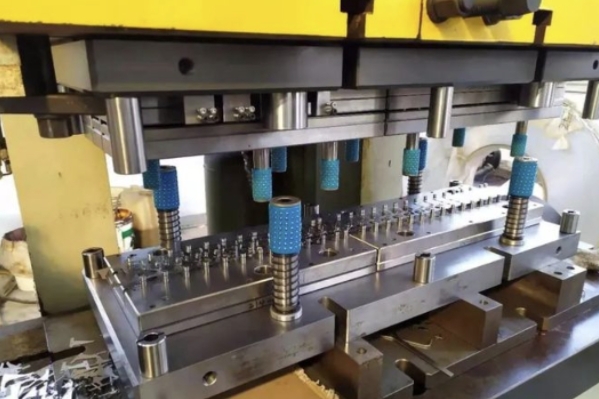

5) Set Up the Press

According to the mold we designed and made, we choose a press with sufficient tonnage and stroke length, fix the mold on the press through the upper and lower templates, and install the automatic feeding mechanism.

6) Run the Production

We load the coils or strips of the specified material into the feed mechanism. After starting the press, the press will continue to cycle and complete all the station actions in sequence. During the trial production, we will check the dimensional accuracy and surface finish of the clamp to ensure that the mold can produce qualified clamps and be ready to enter mass production.

7) Post-Processing (if needed)

We will remove the burrs and sharp edges from the clamp if there is. And also apply surface treatment like powder coating, zinc plating, hot-dip galvanizing to increase corrosion resistance or aesthetic purposes. Perform heat treatment (e.g., hardening, tempering) if additional strength or durability is required.

Besides progressive die stamping, we also make simple die for prototypes, Single punch mold, Compound mold, Transfer mold etc. If your current mold is retired and want to make a new mold for production, please contact with us and we can make per your requirement. In our company, we always make new molds at our cost if old molds are retired and customers still have continuous order. If you are not sure what dies are suitable for your projects, please send us detailed drawings and estimated order volume, we will recommend the most economical die for you per your design, application and yearly demand.