Yixing Technology has developed extensive expertise in sheet metal welding services, providing several competitive advantages to local and international clients in automotive, solar energy, medical device, industrial equipment, electronic industry etc.

✔Wide Welding Types: Our workshop is equipped with high tech welding machines to provide TIG welding, MIG welding, resistance welding, laser welding and robot welding etc.

✔From Thin to Thick Plate: The thickness we can weld ranges from 0.3mm to 25mm.

✔Robotic Welding: We use robotic arms to do welding for high volume production. More consistent and reliable.

✔Material Versatility: Capable of welding stainless steel, aluminum, carbon steel, galvanized sheets, copper alloys and brass alloys.

✔Quality Assurance & Certifications: We stick to ISO9001 quality system. Carry out material coming-in inspection, in process inspection, final inspection and also we can do VT, PT, MT, UT and RT test etc for weldments.

✔One-Stop Fabrication Services: From laser cutting, bending, stamping, machining, welding and anti-rust surface treatment etc— All is done in house!

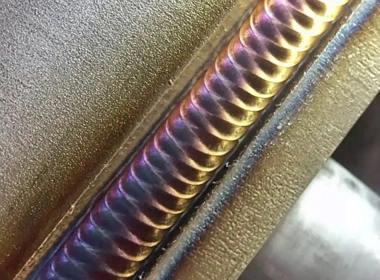

1. TIG Welding (Tungsten Inert Gas Welding)

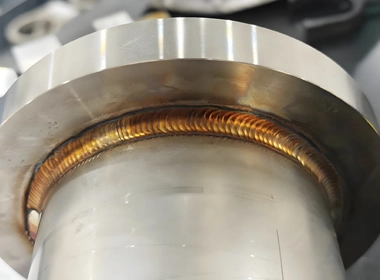

TIG welding utilizes a non-consumable tungsten electrode and inert gas shielding (typically argon or helium) to produce exceptionally clean, high-precision welds. This process offers superior control without spatter, making it ideal for thin materials and critical applications like aerospace components, pressure piping, and artistic metalwork. While capable of joining diverse metals including aluminum, stainless steel, and titanium, the technique demands skilled operators and operates at slower speeds compared to other welding methods. The need for manual filler metal addition further contributes to its reputation as a specialized, high-quality joining process.

2. MIG Welding (Metal Inert Gas Welding)

MIG welding uses a continuously fed wire electrode with argon-CO₂ shielding gas for fast, semi-automated material joining. Delivering higher deposition rates than TIG with less operator skill, it's ideal for thick materials in high-volume applications like auto manufacturing and steel construction. While less precise and prone to spatter, its efficiency and minimal cleanup make it perfect for industrial fabrication prioritizing speed over aesthetics. This productivity-quality balance drives its popularity in mass production and construction projects.

3. Resistance Welding (Spot/Seam Welding)

Resistance welding bonds metals through strategically applied pressure and electrical current, creating intense localized heat at the contact points without requiring filler materials or shielding gas. This rapid, energy-efficient process excels in high-volume sheet metal fabrication - particularly for automotive body panels, battery connections, and household appliances - though its application is constrained by material compatibility issues, thickness limitations (typically under 3mm), and relatively imprecise weld quality compared to other methods. The technology's production speed makes it ideal for assembly lines where these trade-offs are acceptable.

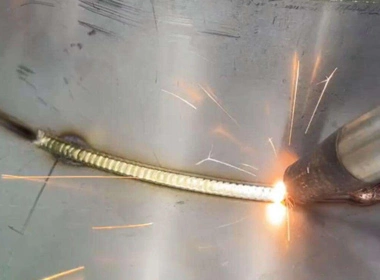

4. Laser Welding

Laser welding delivers micron-level precision by focusing intense light energy to melt and fuse materials with minimal thermal spread, enabling deep, narrow welds ideal for delicate components. This automated process achieves remarkable speeds while maintaining exceptional accuracy, though it faces challenges with reflective surfaces and thicker sections. Its unique capabilities make it indispensable for manufacturing medical implants, microelectronics, and sensitive automotive parts where traditional methods would cause unacceptable distortion or damage. The technology's ability to work with tiny, heat-sensitive components comes with material limitations - particularly with highly conductive metals - requiring careful process optimization for each application.

5. Robot Welding

Robot welding utilizes automated robotic arms to execute precise, pre-programmed welding operations (MIG/TIG/laser) with unmatched consistency, making it ideal for high-volume production lines. While requiring substantial upfront investment in equipment and programming, this technology significantly reduces labor costs, enhances workplace safety by removing operators from hazardous environments, and delivers superior repeatability compared to manual welding. Robotic welding sacrifices flexibility for consistency, struggling with custom jobs human welders handle easily. This makes it ideal for high-volume settings like auto plants where standardization justifies the investment.

Carbon Steel Sheet Metal Welding:Carbon steel has good welding performance and is suitable for almost all welding methods. For example, MIG/MAG can be used for efficient welding of medium and thick plates, TIG can be used for welding high-quality thin and precision parts, resistance welding can be used for spot welding of thin plates, and SAW welding can be chosen for long welds of thick plates.

Stainless Steel Sheet Metal Welding:Stainless steel has certain difficulties in welding due to its special physical and chemical properties, such as high chromium content, thermal sensitivity, and easy deformation. TIG Welding is often chosen for SS304/SS316 (oxide-free precision welds) and MIG welding for thicker plates and laser welding for thin plates.

Aluminum Sheet Metal Welding: The thermal conductivity of aluminum is four times that of steel, and heat is rapidly dissipated. The dense Al₂O₃oxide film on the surface of aluminum (melting point 2050 ℃) is much higher than that of aluminum itself (660 ℃), which can easily lead to incomplete fusion. Recommend using TIG (AC) for welding high-quality thin plates and MIG (pulse) for welding medium thick plates, FSW does not melt and is suitable for high-strength aluminum alloys.

Copper Sheet Metal Welding: Copper has extremely strong thermal conductivity and requires high heat input or preheating. TIG welding of high thermal conductivity pure copper requires preheating, while bronze/brass can be directly welded. Laser welding of thin copper plates requires anti reflection treatment, and brazing (electrical joints to avoid high-temperature deformation) are recommended.

Galvanized Steel Sheet Metal Welding: Zinc coating on the galvanized steel vaporizes at high temps which will cause porosity so we need to adjust parameters or grind off zinc first before welding. Recommend using MIG welding (short-circuit transition) (requires ventilation, zinc vapor is toxic) and resistance welding (zinc layer has less impact during spot welding).

Exceptionally Robust Joints: Welding produces exceptionally robust connections that frequently match or exceed the strength of the parent materials. This makes it particularly valuable for critical applications requiring superior structural integrity, such as in building frameworks, vehicle manufacturing, and aircraft assembly.

Permanent & Leak-Proof Connections: Welding creates molecular-level fusion between materials, offering distinct advantages over mechanical fasteners like bolts or rivets. This permanent bonding solution eliminates the risk of gradual loosening.

Material Versatility: Welding is capable of bonding diverse materials, including carbon steel, corrosion-resistant stainless steel, lightweight aluminum, conductive copper, malleable brass, corrosion-protected galvanized steel, and various other metals and alloys.

Cost & Time Efficiency: By eliminating multiple assembly components like mechanical fasteners and bonding agents, welding significantly streamlines manufacturing processes. Robot welding further enhances production throughput, delivering faster cycle times while maintaining consistent quality.

1. Automotive & Transportation

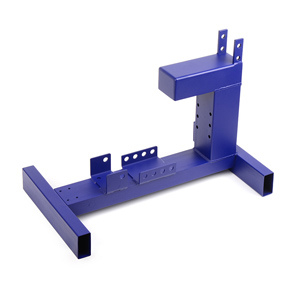

The sheet metal welding parts we make includes body panels welding assembly, welding exhaust systems, welding chassis, welding brackets etc.

2. Construction & Architecture

The sheet metal welding parts we make includes structural steel welding frames, welding roofing parts, HVAC ductwork weldments, and decorative metalwork weldments.

3. Manufacturing & Industrial Equipment

The sheet metal welding parts we make includes welding machinery housings, welding conveyor systems etc.

4. Electronics & Enclosures

The sheet metal welding parts we make includes electrical cabinets, server racks, control panels, and shielding.

5. Medical & Laboratory Equipment

The sheet metal welding parts we make includes patient lift, medical device enclosures, stainless steel workstations etc.

6. Energy & Renewable Sector

The sheet metal welding parts we make includes solar panel frames, wind turbine components, oil/gas pipelines etc.

7. Food & Beverage Industry

The sheet metal welding parts we make includes stainless steel tanks, processing equipment, conveyor systems etc.

8. Furniture & Artistic Metalwork

The sheet metal welding parts we make includes custom furniture, sculptures, railings, and decorative panels.

9. Marine & Shipbuilding

The sheet metal welding parts we make includes stainless steel welding railings, storage tanks, and offshore structures etc.

Expert Sheet Metal Welding Solutions – Precision, Experience, Certification

With 15+ years in sheet metal fabrication, Yixing Technology masters the nuances of welding technologies to select the optimal method for your project. Our certified welding team delivers precision work across all metals, ensuring quality and reliability.

Advanced Welding Capabilities for All Metals & Applications

We expertly perform MIG, TIG, laser, manual, and robotic welding on steel, stainless steel, and aluminum. Our versatile capabilities cover everything from precision thin-gauge welding to heavy-duty thick coatings and high-spec metal fabrication.

Comprehensive Assembly Solutions Beyond Welding

In addition to welding assembly, we expertly handle mechanical fastening, adhesive bonding, and other assembly methods. Our skilled team ensures precise, safe assembly of all components for flawless final products.

Aluminum and aluminum alloys, due to their unique physical and chemical properties, encounter a series of difficulties during the welding process. Specifically, there are several points to consider:

1. Strong oxidation ability

2. Aluminum has a high thermal conductivity and specific heat, resulting in fast thermal conductivity

3. High coefficient of linear expansion

4. Easy to form pores

5. Welding joints are prone to softening

6. Evaporation and burning of alloy elements

7. Aluminum has low strength and plasticity at high temperatures

8. The corrosion resistance of welded joints is lower than that of the base material

9. No color change, making welding operations difficult

Shanghai Yixing has well trained and certified welders to meet customers demands of aluminum welding.

For thin metals, if you are not careful and do not have sufficient control over the heat generated by the welding machine, the metal is easily melted completely. This is what is called burning through.

To weld thin metal, choose an appropriate process (low current TIG or MIG), use smaller diameter welding wires or filler rods, and adjust the travel speed to prevent burn through. Using pulse technology, seam welding, or positioning welding to control heat and allow for cooling time between welds to minimize warping.

1. Using anti deformation method to control welding deformation

In order to offset and compensate for welding deformation, during assembly before welding, the workpiece is first artificially deformed in the opposite direction to the welding deformation. This method is called reverse deformation method. The anti deformation method is the most commonly used method in production, which is usually suitable for controlling the angular deformation and bending deformation of welded parts.

2. Control welding deformation using rigid fixation method

The method of using fixtures, supports, specialized molds, positioning welding, and other methods to increase the rigidity of the structure and reduce welding deformation is called rigid fixation method. The rigid fixation method is simple and easy to implement, and is a commonly used method in production to reduce welding deformation. In production, rigid fixation and anti deformation are commonly used to control welding deformation.

3. Choose a reasonable welding sequence to control welding deformation

The same welding structure, using different welding sequences, often results in different welding deformations. Therefore, the welding sequence that causes the least welding deformation should be selected. Generally, the sequence of assembly before welding is adopted, and the welding deformation of the structure after welding is relatively small.

4. Choose a reasonable welding sequence to control welding deformation

When there are multiple welds on the welding structure, different welding sequences will cause different welding deformations. A reasonable welding sequence refers to: when the weld seam is symmetrically arranged, symmetrical welding should be used; When the weld seam is arranged asymmetrically, the smaller side of the weld seam should be welded first. In addition, methods such as skip welding and segmented back welding have shown good results in controlling welding deformation.

5. Hammering method

By hammering to extend the weld seam, the deformation caused by weld seam shrinkage can be overcome to a certain extent. For example, if wave deformation occurs after thin plate butt welding, a hammer can be used to hammer the weld seam in the length direction to overcome its deformation.

6. Choose a reasonable welding method

Choosing welding methods with relatively concentrated energy, such as CO2 gas shielded welding and plasma arc welding, instead of gas welding and manual arc welding for thin plate welding can reduce deformation.