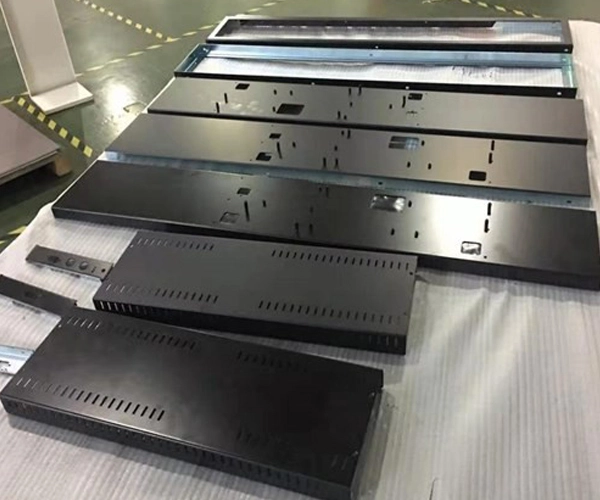

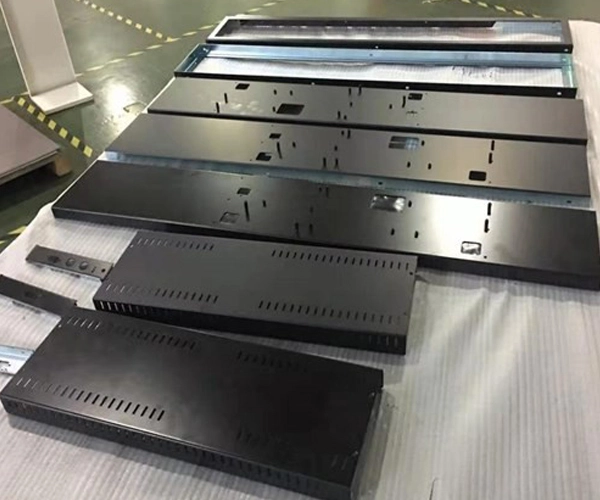

Product Item: L-6

Material: aluminum/carbonsteel/stainless steel

Thickness: 0.5-3mm

Surface treatment: powder coating/anodization/zinc plating

No deburs precision dimension

As already discussed, laser technology has an edge over other cutting methods when it comes to certain qualities. All those can work for your cause if you are aware of them.

The main advantages of Laser cutting:

Great flexibility - One sheet may have 100 different cuts without having to change tools. Also, it is possible to cut all kinds of intricate shapes.

Precision - Accuracy of+/- 0.1 mm gives the possibility to really cater to your most demanding needs. This kind of precision also ensures high quality.

Repeatability - +/- 0.05 mm ensures close to identical details.

Speed - Laser cutters are known for their speed, especially when cutting thin metal sheets.

Saves money - The machines are getting more energy efficient. Shuttle tables reduce the need for handling which means less need for manual labour. Smaller manufacturing costs result in lower total costs for the buyer.

Saving time - Laser cutting is automated. Therefore, it is the machinery that reads the drawings. The drawings only need to include cutting lines. This saves a lot of time in the drawing-room.

Small areas of HAZ - The heat affected zone is an unwanted byproduct of thermal cutting methods. As laser cutting has a small cutting kerf, the heat is not dispersed as heavily as with other cutting methods, leaving a smaller HAZ.

Enclosures

Laser cutting offers a cost-effective way to fabricate device panels, boxes and cases for a variety of applications including rackmounts, "U" and“L" shapes, as well as consoles and consolets.

Chassis

The chassis we fabricate are typically used to house electromechanical controls, from small handheld devices to large industrial testing equipment. All chassis are built to critical dimensions to ensure hole pattern alignment between different parts.

Brackets

Yixing Technology builds custom brackets and miscellaneous laser cutting components, well-suited for either lightweight applications or when a high degree of corrosion-resistance is needed. All hardware and fasteners that are needed can be fully built in.